-

- Sopto Home

-

- Special Topic

-

- Patch Cord Knowledge

-

- Detect optical fiber jumper

Patch Cord Knowledge

- Fiber Optic Connector Ferrule Design

- Fiber Optic Connector Design

- E2000 to ST Fiber Patch Cable Overview

- Acceptable and Unacceptable Fiber Connector End-Face Finishes

- Using Wipes and Cleaning Cassettes to Clean Fiber Patch Cords

- Not-Too-Tight Mating of Fiber Optic Connectors

- Matching Gel and Oils Contamination about Fiber Optic Connectors

- The Effect of Improper Use of Fiber Optic Connectors

- Why Fiber Optic Connectors are Fragile?

SOPTO Special Topic

Certificate

Guarantee

Except products belongs to Bargain Shop section, all products are warranted by SOPTO only to purchasers for resale or for use in business or original equipment manufacturer, against defects in workmanship or materials under normal use (consumables, normal tear and wear excluded) for one year after date of purchase from SOPTO, unless otherwise stated...

Return Policies

Defective products will be accepted for exchange, at our discretion, within 14 days from receipt. Buyer might be requested to return the defective products to SOPTO for verification or authorized service location, as SOPTO designated, shipping costs prepaid. .....

Applications

Fiber Patch Cords have a widely application. Where the need for the optical fiber connection, where you need fiber optic patch cords.

Fiber Patch Cords have a widely application. Where the need for the optical fiber connection, where you need fiber optic patch cords.

Testing Equipment

FTTX+ LAN

Optical Fiber CATV

Optical Communication System

Telecommunication

SOPTO Products

- Fiber Optic Transceiver Module

- High Speed Cable

- Fiber Optical Cable

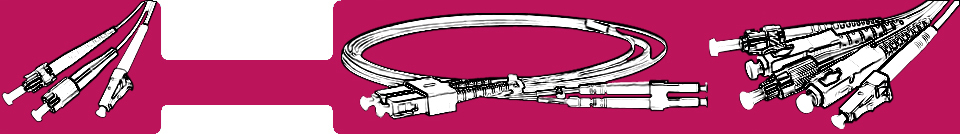

- Fiber Optical Patch Cords

- Splitter CWDM DWDM

- PON Solution

- FTTH Box ODF Closure

- PCI-E Network Card

- Network Cables

- Fiber Optical Adapter

- Fiber Optical Attenuator

- Fiber Media Converter

- PDH Multiplexers

- Protocol Converter

- Digital Video Multiplexer

- Fiber Optical Tools

- Compatible

Related Products

Performance Feature

Good Water-proof

Low insertion loss;

low reflection loss;

Stability, good repeatability;

High-precision ceramic ferrule;

Compatible with NTT standard;

Precision Grinding and fully testing;

Compliance with international standards

Patch Cord Knowledge

Recommended

Ways to detect if the optical fiber jumper is qualified

The Optical Fiber Interface

Optical fiber interface is the physical interface used to connect optical fiber cable. The principle of optical fiber interface is the total reflection of using the light from the optically denser medium into optically thinner medium. Usually, the optical fiber interface is divided into SC, ST, FC and other types which are developed by Japan's NTT.

FC is the abbreviation of Ferrule Connector. Its’ external strengthening way is to use a metal sleeve, and the fastening methods is turnbuckle. The ST interface is often used for 10Base-F. The SC interface is often used for 100Base-FX.

Insert loss meter

Using Visual Fault Locator to detect the light whether can through the jumper or not.

If the answer is yes, that means the fiber is not broken, and then measures the indicators.

The general telecom level index:

Insertion loss <0.3dB; Return loss >45dB;

The Fiber Jumper performance testing includes:

1. Detection of optical performance, including return loss/insertion loss test. The Test instrument can use FibKey 7602 return loss/insertion loss integration tester.

2. End face geometry test. The test parameters are including the radius of curvature, the vertex offsets and the height of fiber-optic. The Test instrument is interferometer. Lots of people use AC/NC3000 or CC6000 to test. Because of superior cost-effective, more and more factories use the CC6000 to test.

3. Optical fiber end face scratch test. Adopts FIBER OPTIC VIDEO SCOPE to reach the clearest images and the operation is extremely simple. For example, many factories use FibView FV – 400PA to inspect. Some customers are also use FibKey-5600— the variable multiple magnifier to detect.This instrument can set 400 times, 200 times and 80 times magnifying glass at an organic whole. It is clear and convenient to observe the fiber end face and insert core surface. Of course you can also use the software for automatic inspection.

4. Fiber tension testing. This step is to test the optical fiber connector to withstand the size of the tensile force.

5. The experiment of environmental temperature. It is need to test the performance index of optical fiber connector in different environmental temperature.

Related Knowledge:

- LSZH Material of Fiber Optic Patch Cord

- Guide to Identify Fiber Optic Connectors

- Fiber Patch Cord Connector and Color Codes

- Fiber Connector Ferrule Shapes and Polishes

- Splicing of fiber patch cord

Guess Products You May Like: