-

- Sopto Home

-

- Special Topic

-

- Patch Cord Knowledge

-

- The Effect of Improper Use of Fiber Optic Connectors

Patch Cord Knowledge

- Fiber Optic Connector Ferrule Design

- Fiber Optic Connector Design

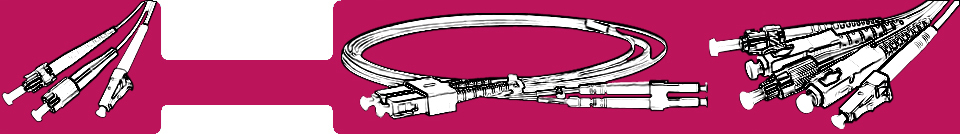

- E2000 to ST Fiber Patch Cable Overview

- Acceptable and Unacceptable Fiber Connector End-Face Finishes

- Using Wipes and Cleaning Cassettes to Clean Fiber Patch Cords

- Not-Too-Tight Mating of Fiber Optic Connectors

- Matching Gel and Oils Contamination about Fiber Optic Connectors

- The Effect of Improper Use of Fiber Optic Connectors

- Why Fiber Optic Connectors are Fragile?

SOPTO Special Topic

Certificate

Guarantee

Except products belongs to Bargain Shop section, all products are warranted by SOPTO only to purchasers for resale or for use in business or original equipment manufacturer, against defects in workmanship or materials under normal use (consumables, normal tear and wear excluded) for one year after date of purchase from SOPTO, unless otherwise stated...

Return Policies

Defective products will be accepted for exchange, at our discretion, within 14 days from receipt. Buyer might be requested to return the defective products to SOPTO for verification or authorized service location, as SOPTO designated, shipping costs prepaid. .....

Applications

Fiber Patch Cords have a widely application. Where the need for the optical fiber connection, where you need fiber optic patch cords.

Fiber Patch Cords have a widely application. Where the need for the optical fiber connection, where you need fiber optic patch cords.

Testing Equipment

FTTX+ LAN

Optical Fiber CATV

Optical Communication System

Telecommunication

SOPTO Products

- Fiber Optic Transceiver Module

- High Speed Cable

- Fiber Optical Cable

- Fiber Optical Patch Cords

- Splitter CWDM DWDM

- PON Solution

- FTTH Box ODF Closure

- PCI-E Network Card

- Network Cables

- Fiber Optical Adapter

- Fiber Optical Attenuator

- Fiber Media Converter

- PDH Multiplexers

- Protocol Converter

- Digital Video Multiplexer

- Fiber Optical Tools

- Compatible

Related Products

Performance Feature

Good Water-proof

Low insertion loss;

low reflection loss;

Stability, good repeatability;

High-precision ceramic ferrule;

Compatible with NTT standard;

Precision Grinding and fully testing;

Compliance with international standards

Patch Cord Knowledge

Recommended

The Effect of Improper Use of Fiber Optic Connectors

Fiber optic connector maintenance is a big topic. The following figure shows a close-up of a clean connector endface.

.png)

Figure 1. A clean and problem-free connector

In contrast, the following figure shows a connector end that was used with a cable end that avoided the alignment key. This may have been caused by a temporary ferrule without a key, or possibly a mismatched long ferrule put into a short connector assemble. Material is smeared and ground into the endface causing light scattering and poor reflection.

.png)

Figure 2. A dirty endface from poor cleaning

Even worse, the following figure shows that if the connector was used continuously this way, it will grind off the glass face and destroy the connector.

Figure 3. A damaged connector

The above figure shows a damaged connector from abuse and using an unkeyed ferrule to mate with this cable. The top left image is 50X. The black center is the glass fiber and the ring around it is the centering “stake”. The bottom two are at 200X and the top right is the glass fiber end at 400X showing the ringed damage on the glass.

Repeated connections without removing the particles or using improper tools can lead to physical damage of the glass fiber endface as shown in the following pictures. Where the damage is severe, the damage on one connector can be transferred to another good connector that comes in contact with it.

.png)

Figure 4. A damaged fiber end from using a pin on it

.png)

Figure 5. A close-up (about 100x) showing the pin broke off a piece of the glass fiber and moved it out of position

.png)

Figure 6. At 50x the damage to another connector endface, from grit and repeated non-cleaning, is seen

.png)

Figure 7. At 200x, the damage and pitting to the connector

The cure is disciplined connector care. Soft swabs should be used – never use metal or sharp objects. Some connectors have a soft endface material that can be very easily scratched and damaged.

In the figure 1, for example, the result of using a pin on the connector surface is seen. In figure 2, a close-up of this damaged connector, not only is there gouging in the endface around the fiber, but the glass fiber itself has been chipped off and broken. Broken or damaged glass can lead to a number of problems that are often ascribed to other causes. This connector will probably damage any other fiber that is mated to it.

In the figure 3 and figure 4 above, another connector is seen with severe abuse. In this example, the soft ferrule core was pushed away from the glass and there is pitting in the fiber end. In addition, the glass fiber is sticking up almost 3um above the uneven surface (from severe wear of the soft metal that was once flush with the glass fiber).

Sopto supply fiber optic patch cords with good quality fiber optic connectors, like LC, ST, FC, SC and so on. For the newest quotes, please contact a Sopto representative by calling 86-755-36946668, or by sending an email to info@sopto.com. For more info, please browse our website.