-

- Sopto Home

-

- Special Topic

-

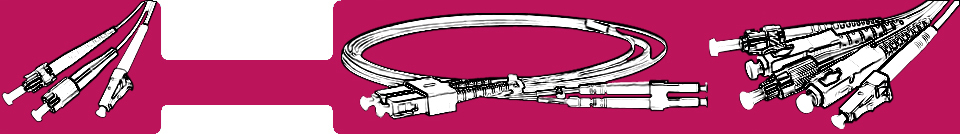

- Patch Cord Knowledge

-

- Fiber Optic Connector Ferrule Design

Patch Cord Knowledge

- Fiber Optic Connector Ferrule Design

- Fiber Optic Connector Design

- E2000 to ST Fiber Patch Cable Overview

- Acceptable and Unacceptable Fiber Connector End-Face Finishes

- Using Wipes and Cleaning Cassettes to Clean Fiber Patch Cords

- Not-Too-Tight Mating of Fiber Optic Connectors

- Matching Gel and Oils Contamination about Fiber Optic Connectors

- The Effect of Improper Use of Fiber Optic Connectors

- Why Fiber Optic Connectors are Fragile?

SOPTO Special Topic

Certificate

Guarantee

Except products belongs to Bargain Shop section, all products are warranted by SOPTO only to purchasers for resale or for use in business or original equipment manufacturer, against defects in workmanship or materials under normal use (consumables, normal tear and wear excluded) for one year after date of purchase from SOPTO, unless otherwise stated...

Return Policies

Defective products will be accepted for exchange, at our discretion, within 14 days from receipt. Buyer might be requested to return the defective products to SOPTO for verification or authorized service location, as SOPTO designated, shipping costs prepaid. .....

Applications

Fiber Patch Cords have a widely application. Where the need for the optical fiber connection, where you need fiber optic patch cords.

Fiber Patch Cords have a widely application. Where the need for the optical fiber connection, where you need fiber optic patch cords.

Testing Equipment

FTTX+ LAN

Optical Fiber CATV

Optical Communication System

Telecommunication

SOPTO Products

- Fiber Optic Transceiver Module

- High Speed Cable

- Fiber Optical Cable

- Fiber Optical Patch Cords

- Splitter CWDM DWDM

- PON Solution

- FTTH Box ODF Closure

- PCI-E Network Card

- Network Cables

- Fiber Optical Adapter

- Fiber Optical Attenuator

- Fiber Media Converter

- PDH Multiplexers

- Protocol Converter

- Digital Video Multiplexer

- Fiber Optical Tools

- Compatible

Related Products

Performance Feature

Good Water-proof

Low insertion loss;

low reflection loss;

Stability, good repeatability;

High-precision ceramic ferrule;

Compatible with NTT standard;

Precision Grinding and fully testing;

Compliance with international standards

Patch Cord Knowledge

Recommended

Fiber Optic Connector Ferrule Design

In the earliest days of optical fiber jointing the sophisticated manufacturing techniques now associated with demountable connectors were not available. Instead existing components or technology had to be used or modified to provide an acceptable level of insertion loss.

The most obvious method was to use a machined V-groove as an alignment tool and to secure the two fiber ends within metal tubes or ferrules in such a way as to ensure acceptable performance. It is relatively easy to produce V-grooves and tubes to the required tolerances: the difficult task was to align the fibers within the tubes themselves.

These basic ferrule designs resorted to watch jewels made from synthetic ruby or sapphire which were inserted into the tubes (see the following figure).

These jewelled ferrules are still used as methods of connection to test equipment as they are simple to terminate and their performance is limited by the hole diameter, concentricity and fitting tolerances of the jewel within the tube.

.png)

Basic ferrule designs resorted to watch jewels

The first true demountable connector was the SMA (subminiature ‘A’) which was loosely based upon the design of the electrical connector of the same name.

It featured an all-metal ferrule together with a rear body which allowed stable connection to the incoming cable. The rear body provided connection to the alignment tool (a threaded tube) by means of a captive nut.

Connector. The complete assembly attached to the fiber optic cable. In general these are of male configuration requiring a female component to allow the jointing of two connectors. In technical literature the connector may be termed a plug.

Adaptor. The female component used to join two connectors. The adaptor is responsible for providing the alignment of the connectors and the fibers within them. Other terms frequently used are: uniters, couplers, sockets, receptacles.

Termination. The process of attaching a connector is to a fiber optic cable element (and also the name given to the completed assembly).

Most fiber optic connectors comprise a ferrule (or in the case of multi-element devices, a number of ferrules) which is responsible for the control of fiber alignment and a rear body which is responsible for the attachment of the connector to the cable. The rear body can be complex in construction and has additional responsibilities for the connection of the connector to the adaptor.

The mechanics of the ferrules and rear bodies vary from connector to connector and will be discussed for each connector type. The ferrule is usually made of a ceramic material, because of its hardness and thermal stability, although polymer ferrules are now accepted as being nearly as good.

The particular ceramic is known as zirconia (zirconium dioxide ZrO2) chosen because its hardness and thermal coefficient of expansion is very similar to glass. It also polishes well. To be more specific the material is usually tetragonal zirconia poly-crystal, which is zirconia and yttria (yttrium oxide Y2O3).

For the quotes of our fiber patch cords and fiber connectors, please contact a Sopto representative by calling 86-755-36946668, or by sending an email to info@sopto.com. For more info, please browse our website.