-

- Sopto Home

-

- Special Topic

-

- Patch Cord Knowledge

-

- Patch Cord Management Appendix A

Patch Cord Knowledge

- Fiber Optic Connector Ferrule Design

- Fiber Optic Connector Design

- E2000 to ST Fiber Patch Cable Overview

- Acceptable and Unacceptable Fiber Connector End-Face Finishes

- Using Wipes and Cleaning Cassettes to Clean Fiber Patch Cords

- Not-Too-Tight Mating of Fiber Optic Connectors

- Matching Gel and Oils Contamination about Fiber Optic Connectors

- The Effect of Improper Use of Fiber Optic Connectors

- Why Fiber Optic Connectors are Fragile?

SOPTO Special Topic

Certificate

Guarantee

Except products belongs to Bargain Shop section, all products are warranted by SOPTO only to purchasers for resale or for use in business or original equipment manufacturer, against defects in workmanship or materials under normal use (consumables, normal tear and wear excluded) for one year after date of purchase from SOPTO, unless otherwise stated...

Return Policies

Defective products will be accepted for exchange, at our discretion, within 14 days from receipt. Buyer might be requested to return the defective products to SOPTO for verification or authorized service location, as SOPTO designated, shipping costs prepaid. .....

Applications

Fiber Patch Cords have a widely application. Where the need for the optical fiber connection, where you need fiber optic patch cords.

Fiber Patch Cords have a widely application. Where the need for the optical fiber connection, where you need fiber optic patch cords.

Testing Equipment

FTTX+ LAN

Optical Fiber CATV

Optical Communication System

Telecommunication

SOPTO Products

- Fiber Optic Transceiver Module

- High Speed Cable

- Fiber Optical Cable

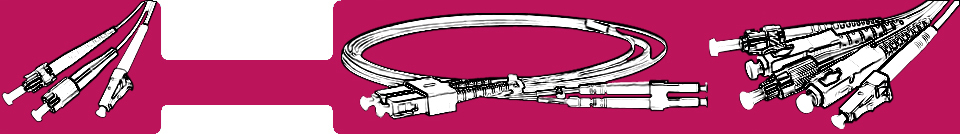

- Fiber Optical Patch Cords

- Splitter CWDM DWDM

- PON Solution

- FTTH Box ODF Closure

- PCI-E Network Card

- Network Cables

- Fiber Optical Adapter

- Fiber Optical Attenuator

- Fiber Media Converter

- PDH Multiplexers

- Protocol Converter

- Digital Video Multiplexer

- Fiber Optical Tools

- Compatible

Related Products

Performance Feature

Good Water-proof

Low insertion loss;

low reflection loss;

Stability, good repeatability;

High-precision ceramic ferrule;

Compatible with NTT standard;

Precision Grinding and fully testing;

Compliance with international standards

Patch Cord Knowledge

Recommended

Patch Cord Management Appendix A

Cleaning and Inspection of Optical Fiber Connectors

Cleanliness of fiber optic connections is critical to the performance of optical communication networks. Contamination on a connector end face, even if only at the microscopic level, can create severe problems. Traditional single mode fiber optic core diameters are approximately 9 microns (0.00035 inches). By comparison, a human hair is 50 microns or larger in diameter. Contamination that blocks the fiber core generates strong back reflections (Return Loss), and may effect attenuation (Insertion Loss). Loose contamination on the connector end face that may not block the core may move during de-mating, or may prevent physical glass-to-glass contact required for proper signal transmission. Rigid contamination trapped between connector end faces may permanently damage the fiber core(s).

Dry contaminates are relatively simple to remove compared to oils and films which naturally occur with human contact, vapor condensation, and solvent evaporation. SOPTO offers a complete Fiber Optic Connector.

Cleaning and Inspection Kit and a Fiber Optic Connector Consumable Kit can service SC, ST, LC and MPO connectors.

Below is a list of basic cleaning steps and recommendations for each connector type. After cleaning, always inspect the connector end face with an appropriate microscope to verify that it is free of dirt, smudges and/or scratches. For complete instructions covering the use of the SOPTO Fiber Optic Connector Cleaning and Inspection Kit, please refer to the SOTPO Fiber Optic Connector Cleaning and Inspection Kit instruction sheet.

Cleaning Single Fiber Connectors (LC/SC/ST) and Adapters

Connector Ferrule – Exposed End face

Dry Cleaning: Using reel-based cassette cleaner with medium pressure, wipe connector endface against dry cleaning cloth (single swipe per exposure) in one direction. For angled physical contact (APC) polished connectors, ensure that entire end face surface mates with the cleaning cloth. Dry cleaning will generally remove airborne contamination and should be attempted first. Inspect connector end face for contamination after cleaning.

Another method is to use single fiber In-bulkhead cleaners (I.B.C) that are especially designed for both physical contact (PC) and angled physical contact (APC) polished connectors. These devices feed a cleaning cloth across a head while the head rotates. Cleaning cloth is advanced to ensure it is clean. Install connector into a clean adapter and after inserting cleaner tip inside the adapter from the opposite end, press lever to initiate cleaning. Some single fiber IBC cleaners offer intuitive cleaning with audible click when engaged. Always inspect connector end face for contamination after cleaning.

Wet Cleaning: Lightly moisten portion of a lint free wipe with fiber optic cleaning solution (or > 91% Isopropyl Alcohol) and by applying medium pressure, first wipe end face against wet area and then onto dry area to clean potential residue from the end face. For APC polished connectors, ensure entire end face surface mates with the cleaning wipes. Wet cleaning is more aggressive than dry cleaning, and will remove airborne contamination as well as light oil residue and films. Perform dry cleaning as described above after wet cleaning and inspect connector end face for contamination after cleaning.

Caution: Always clean sides and tip of ferrule. Core alignment may be affected if ferrule is not thoroughly cleaned.

Connector Ferrule – Bulkhead Adapter Application

Dry Cleaning: Insert appropriate size cleaning stick tip into the adapter until a contact is made with the connector on the opposite end. Cleaning sticks are available for both 1.25 mm ferrule connectors (LCs) and 2.5 mm ferrule connectors (SC and ST). Rotate the cleaning stick with medium pressure in one circular motion as it is pulled from the adapter. Inspect end face for any contamination after cleaning.

Another method is to use In-bulkhead cleaners (I.B.C) that are especially designed for both physical contact (PC) and angled physical contact (APC) polished connectors. Insert cleaner tip inside the adapter until a contact is made with the connector on opposite end and press lever to initiate cleaning. Some single fiber IBC cleaners offer intuitive cleaning with audible click when engaged. Inspect connector end face for contamination after cleaning.

Wet Cleaning: Insert a lightly moistened appropriate size cleaning stick tip with fiber optic cleaning solution (or > 91% Isopropyl alcohol) into the adapter until a contact is made with the connector on opposite end. Rotate the cleaning stick with medium pressure in one circular motion as it is pulled from the adapter. Follow up with a dry cleaning stick and complete with dry cleaning method using In-bulkhead- cleaners (I.B.C). Always inspect connector end face for contamination after cleaning.

Caution: Discard cleaning sticks after each use. Do not turn the cleaning stick back and forth pressing against connector end face, this may cause scratches if a large contamination is present.

Single Fiber Adapters – Exposed/Bulkhead Adapter Application

Dry Cleaning: For both exposed and connector mated adapter, insert dry adapter cleaning stick (or fiber adapter sleeve brush) inside the adapter and pull out with twisting motion, cleaning inside surface of alignment sleeve. After cleaning adapter with connector installed on one end, inspect connector end face for contamination.

Wet Cleaning: For both exposed and connector mated adapter, insert adapter cleaning stick (or fiber adapter sleeve brush) moistened with fiber optic cleaning solution (or > 91% Isopropyl Alcohol) inside the adapter and pull out with twisting motion, cleaning inside surface of alignment sleeves. Follow up with a dry swab. After cleaning adapter with connector installed on one end, inspect connector end face for contamination.

Caution: Discard cleaning sticks after each use. Do not rotate the cleaning stick back and forth while pressed against connector end face; this may cause scratches if a large contamination is present

Cleaning Multi-Fiber Array Connector (MPO) and Adapter

Connector Ferrule – Exposed Endface

Dry Cleaning: Using reel-based cassette cleaner with medium pressure, wipe against dry cleaning cloth (single swipe per exposure) in one direction. There are special cleaners available, which can be used for the pinned and the unpinned (PC and APC polished) MPO connectors. For APC MPO connectors, ensure that entire endface surface mates with the cleaning cloth. Dry cleaning will generally remove airborne contamination and should be attempted first. Always inspect connector endface for contamination after cleaning.

Another method is to use reel based MPO In-bulkhead cleaner (IBC) especially designed for cleaning both the pinned and the unpinned (PC and APC polished) MPO connectors. Insert MPO connector into the cap at the tip into the cleaner, and rotate the cleaner wheel to clean the connector endface. Always inspect connector endface for contamination after cleaning.

Wet Cleaning: For unpinned MPO connector, lightly moisten lint free wipe with fiber optic cleaning solution (or > 91% Isopropyl Alcohol) and by applying medium pressure, wipe endface of the MPO connector in a direction perpendicular to fiber array. Repeat process using dry lint-free wipe. For APC MPO connectors, ensure that entire endface surface mates with the cleaning cloth. Follow up with dry cleaning using MPO In-bulkhead cleaner (IBC) as described above and always inspect connector endface for contamination after cleaning.

For wet cleaning of pinned MPO connector, fold the moistened wipe and using creased portion with medium pressure, wipe endface of the MPO connector in a direction perpendicular to fiber array. Repeat process using dry lint-free wipe. For APC MPO connectors, ensure that entire endface surface mates with the cleaning cloth. Follow up with dry cleaning using MPO In-bulkhead cleaner (IBC) as described above and always inspect connector endface for contamination after cleaning.

Another wet cleaning method for both pinned and unpinned MPO connector is to use lightly moistened 2.5 mm SC/ST cleaning stick tip with fiber optic cleaning solution (or > 91% Isopropyl alcohol). With damp tip, clean the pins by holding the tip parallel to pins such that the tip end contacts ferrule. Applying medium pressure, wipe the cylindrical surface of the pins, the connector endface in direction perpendicular to fiber array and all the way around each pin. Repeat process using dry cleaning stick tip. Follow up with dry cleaning as described above. Always inspect connector endface for contamination after cleaning.

Caution: To prevent scratching the end face, always clean the MPO connectors with a cleaning motion from top to bottom perpendicular to fiber array. Never clean the MPO connector by rubbing across it from side to side (parallel to fiber array). Discard cleaning sticks after each use.

Connector Ferrule – Bulkhead Adapter Application

Dry Cleaning: Insert the tip of In-bulkhead cleaners (IBC), especially designed for both the pinned and the unpinned (PC and APC polished) MPO connectors, inside the MPO adapter and rotate the cleaner wheel to clean the connector end face. Inspect connector end face for contamination after cleaning.

Wet Cleaning: Lightly moistened 2.5 mm SC/ST cleaning stick tip with fiber optic cleaning solution (or > 91% Isopropyl alcohol) into the adapter until a contact is made with the connector on opposite end. Clean the pins by holding the tip parallel to pins such that the tip end contacts ferrule and wipe the cylindrical surface of the pins.

Applying medium pressure, wipe the end face in direction perpendicular to fiber array and all the way around each pin. Follow up with dry cleaning stick tip and tip and complete with dry cleaning using MPO In-bulkhead cleaner (IBC) as described above. Always inspect connector end face for contamination after cleaning.

Caution: Discard cleaning sticks after each use. Do not turn the cleaning stick back and forth pressing against connector end face; this may cause scratches if a large contamination is present

MPO Adapter - Exposed/ Bulkhead Adapter Application

Wet Cleaning: Remove MPO connectors from adapters. Wipe inside surface with cleaning stick moistened with fiber optic cleaning solution (or > 91% Isopropyl Alcohol). Follow up with dry cleaning stick. After cleaning adapter with connector installed on one end, inspect connector end face for contamination.

Warning

As compressed air products have the potential to deposit moisture and propellant debris on critical optical surface, SOPTO does not recommend the use of any canned air product when cleaning a fiber optic connector surface.

Note: All other manufacturer’s equipment and devices that are part of the system installation should be cleaned according to the appropriate manufacturer’s recommended cleaning procedures.

Related Knowledge:

- Guide to Identify Fiber Optic Connectors

- Patch Cord Management Appendix B

- Protecting Splices of fiber Patch Cord

- Best Practice for Fiber Cabling