-

- Sopto Home

-

- Special Topic

-

- Patch Cord Knowledge

-

- Protecting Splices of fiber Patch Cord

Patch Cord Knowledge

- Fiber Optic Connector Ferrule Design

- Fiber Optic Connector Design

- E2000 to ST Fiber Patch Cable Overview

- Acceptable and Unacceptable Fiber Connector End-Face Finishes

- Using Wipes and Cleaning Cassettes to Clean Fiber Patch Cords

- Not-Too-Tight Mating of Fiber Optic Connectors

- Matching Gel and Oils Contamination about Fiber Optic Connectors

- The Effect of Improper Use of Fiber Optic Connectors

- Why Fiber Optic Connectors are Fragile?

SOPTO Special Topic

Certificate

Guarantee

Except products belongs to Bargain Shop section, all products are warranted by SOPTO only to purchasers for resale or for use in business or original equipment manufacturer, against defects in workmanship or materials under normal use (consumables, normal tear and wear excluded) for one year after date of purchase from SOPTO, unless otherwise stated...

Return Policies

Defective products will be accepted for exchange, at our discretion, within 14 days from receipt. Buyer might be requested to return the defective products to SOPTO for verification or authorized service location, as SOPTO designated, shipping costs prepaid. .....

Applications

Fiber Patch Cords have a widely application. Where the need for the optical fiber connection, where you need fiber optic patch cords.

Fiber Patch Cords have a widely application. Where the need for the optical fiber connection, where you need fiber optic patch cords.

Testing Equipment

FTTX+ LAN

Optical Fiber CATV

Optical Communication System

Telecommunication

SOPTO Products

- Fiber Optic Transceiver Module

- High Speed Cable

- Fiber Optical Cable

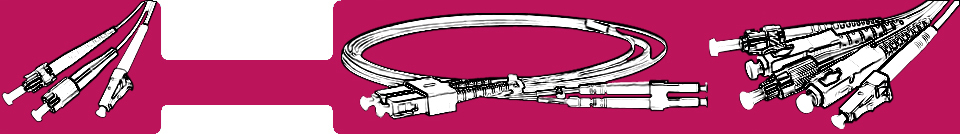

- Fiber Optical Patch Cords

- Splitter CWDM DWDM

- PON Solution

- FTTH Box ODF Closure

- PCI-E Network Card

- Network Cables

- Fiber Optical Adapter

- Fiber Optical Attenuator

- Fiber Media Converter

- PDH Multiplexers

- Protocol Converter

- Digital Video Multiplexer

- Fiber Optical Tools

- Compatible

Related Products

Performance Feature

Good Water-proof

Low insertion loss;

low reflection loss;

Stability, good repeatability;

High-precision ceramic ferrule;

Compatible with NTT standard;

Precision Grinding and fully testing;

Compliance with international standards

Patch Cord Knowledge

Recommended

Protecting Splices

Splices require placement in a protective case. They are generally placed in a splice tray which is then placed inside a splice closure for OSP installations or a patch panel box for premises applications. At splice closures and at each end, cables with metallic shielding or strength members must be properly grounded and bonded.

- Which Splice ?

If cost is the issue, we've given you the clues to make a choice: fusion requires expensive equipment and but makes cheap splices, while Mechanical Splices require inexpensive equipment and expensive splice hardware. So if you make a lot of splices (like thousands in an big telco or CATV network) use fusion splices. If you need just a few, use mechanical splices.

Fusion splices give very low back reflections and are preferred for singlemode high speed digital or CATV networks. However, they may not work well some multimode fibers, so mechanical splices may be preferred for MM, unless it is an underwater or aerial application, where the greater reliability of the fusion splice is preferred.

- Making Good Splices

Making consistently low loss splices depends on proper techniques and keeping equipment in good shape. Cleanliness is a big issue, of course. Fiber strippers should be kept clean and in good condition and be replaced when nicked or worn. Cleavers are most important, as the secret to good splices - either fusion or mechanical - is having good cleaves on both fibers. Keep cleavers clean and have the scribing blades aligned and replaced regularly.

Fusion splicers should be properly maintained and fusing parameters set for the fibers being spliced. For mechanical splices, light pressure on the fiber to keep the ends together while crimping is important. Use a visual fault locator (VFL) to optimize the splice before crimping if possible.

Related Knowledge: