-

- Sopto Home

-

- Special Topic

-

- Patch Cord Knowledge

-

- Patch Cord Management Appendix B

Patch Cord Knowledge

- Fiber Optic Connector Ferrule Design

- Fiber Optic Connector Design

- E2000 to ST Fiber Patch Cable Overview

- Acceptable and Unacceptable Fiber Connector End-Face Finishes

- Using Wipes and Cleaning Cassettes to Clean Fiber Patch Cords

- Not-Too-Tight Mating of Fiber Optic Connectors

- Matching Gel and Oils Contamination about Fiber Optic Connectors

- The Effect of Improper Use of Fiber Optic Connectors

- Why Fiber Optic Connectors are Fragile?

SOPTO Special Topic

Certificate

Guarantee

Except products belongs to Bargain Shop section, all products are warranted by SOPTO only to purchasers for resale or for use in business or original equipment manufacturer, against defects in workmanship or materials under normal use (consumables, normal tear and wear excluded) for one year after date of purchase from SOPTO, unless otherwise stated...

Return Policies

Defective products will be accepted for exchange, at our discretion, within 14 days from receipt. Buyer might be requested to return the defective products to SOPTO for verification or authorized service location, as SOPTO designated, shipping costs prepaid. .....

Applications

Fiber Patch Cords have a widely application. Where the need for the optical fiber connection, where you need fiber optic patch cords.

Fiber Patch Cords have a widely application. Where the need for the optical fiber connection, where you need fiber optic patch cords.

Testing Equipment

FTTX+ LAN

Optical Fiber CATV

Optical Communication System

Telecommunication

SOPTO Products

- Fiber Optic Transceiver Module

- High Speed Cable

- Fiber Optical Cable

- Fiber Optical Patch Cords

- Splitter CWDM DWDM

- PON Solution

- FTTH Box ODF Closure

- PCI-E Network Card

- Network Cables

- Fiber Optical Adapter

- Fiber Optical Attenuator

- Fiber Media Converter

- PDH Multiplexers

- Protocol Converter

- Digital Video Multiplexer

- Fiber Optical Tools

- Compatible

Related Products

Performance Feature

Good Water-proof

Low insertion loss;

low reflection loss;

Stability, good repeatability;

High-precision ceramic ferrule;

Compatible with NTT standard;

Precision Grinding and fully testing;

Compliance with international standards

Patch Cord Knowledge

Recommended

Patch Cord Management Appendix B

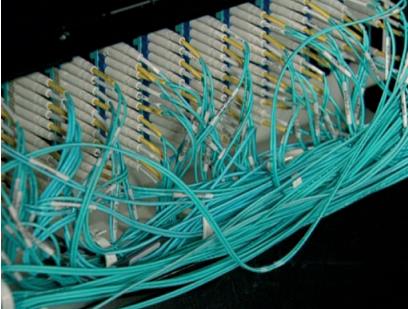

End-to-end cabling connections of all types are only as strong as their weakest link, so you need to be sure you manage patch cords properly. Patch panels that look like this compromise the performance and reliability of the network.

Planning - moves, adds or changes should be initiated with a change request, which may be paper based or electronic.

Attempting to save time by not following proper cord routing will eventually lead to mistakes and difficulty routing and tracing cords.

The performance of the end-to-end channel is determined by the lowest performing component. Make sure you know the specifications and design of your cabling infrastructure, and ensure cords are matched to the cabling.

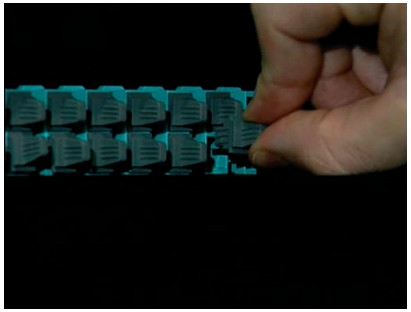

Once you know you have the right cords, consider how they will be installed on the patch panel. Key factors are routing, patch cord length and density. For efficient routing, find the best path between the ports to be connected. Avoid routing cords through troughs and guides that are already congested.

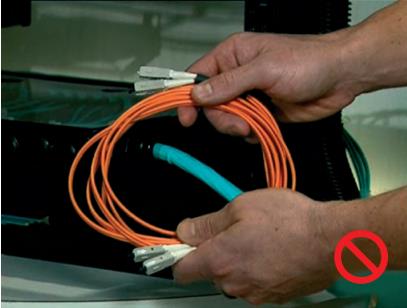

When working with optical fiber cords, pay attention to the core diameter.

A large attenuation penalty will occur when using 62.5 micron multimode cords in a

50 micron cabling plant, and vice versa.

Single mode cords must be used with single mode cabling, preferably also matching the mode field diameter of the installed fiber

Avoid field polished optical fiber cords. Factory terminated cords must be used to achieve optimal performance and ensure warranty coverage.

Inspect fiber cords for physical damage including stress marks from sharp bends on the sheath, or damage to connectors

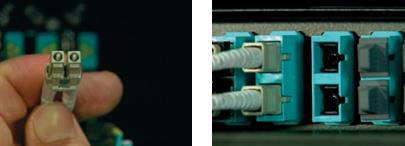

Cleanliness is vital in fiber optic connections, including LC, SC and MPO connections.

Special care is needed with connector ends on patch cords, connector ends on panels, and connector ends on network equipment. It is recommended to clean each connector before a connection is made, using the appropriate cleaning kit

– See Appendix A.

Ensure unused optical fiber ports are covered. The lasers used in optical fiber may cause irreparable damage to the retina. Never look into an energized fiber.

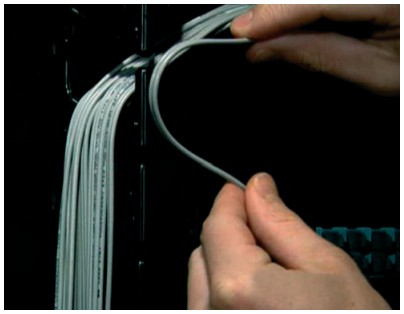

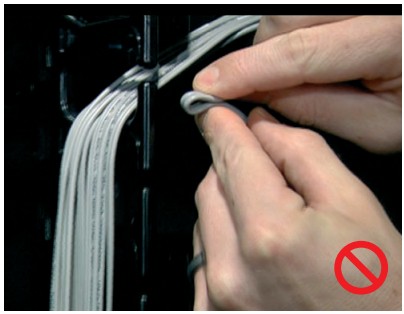

Always maintain the correct bend radius for copper and optical cords.

Exceeding the bend radius of copper or optical fiber cords will result in adverse impact on channel performance.

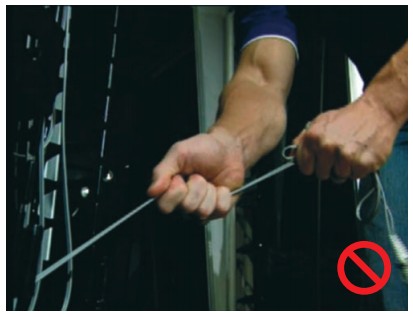

Be careful not to use excessive force during the patching process. This can stress cords and connectors reducing performance.

If you need to use force when pulling a cord, something is wrong. Find the problem and fix it before proceeding.

Correct bundling of cords is also a key to efficient cord management, but takes care not to tighten ties to the point where cords cannot slide freely in the bundle. Be sure to use products that are manufactured for this purpose.

Any unused cords should always be removed from the panel before new ones are added.

Accurate labeling is essential. Labels should be visible and durable, and easily read by anyone carrying out work on the panel. Labels should be printed by a device designed for the purpose.

Validation - time taken to make a final visual inspection is a good investment since mistakes can cause costly disruption and re-work. When patch panels are mounted in enclosures, ensure these are securely closed and, where necessary, locked. Finally, update system documentation and close the work order associated with the completed change request.

Related Knowledge: