-

- Sopto Home

-

- Special Topic

-

- Patch Cord Knowledge

-

- Patch Cord-Inspection and Cleaning are Critical

Patch Cord Knowledge

- Fiber Optic Connector Ferrule Design

- Fiber Optic Connector Design

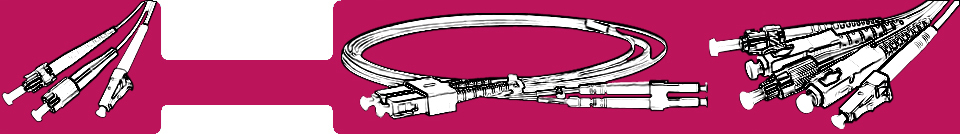

- E2000 to ST Fiber Patch Cable Overview

- Acceptable and Unacceptable Fiber Connector End-Face Finishes

- Using Wipes and Cleaning Cassettes to Clean Fiber Patch Cords

- Not-Too-Tight Mating of Fiber Optic Connectors

- Matching Gel and Oils Contamination about Fiber Optic Connectors

- The Effect of Improper Use of Fiber Optic Connectors

- Why Fiber Optic Connectors are Fragile?

SOPTO Special Topic

Certificate

Guarantee

Except products belongs to Bargain Shop section, all products are warranted by SOPTO only to purchasers for resale or for use in business or original equipment manufacturer, against defects in workmanship or materials under normal use (consumables, normal tear and wear excluded) for one year after date of purchase from SOPTO, unless otherwise stated...

Return Policies

Defective products will be accepted for exchange, at our discretion, within 14 days from receipt. Buyer might be requested to return the defective products to SOPTO for verification or authorized service location, as SOPTO designated, shipping costs prepaid. .....

Applications

Fiber Patch Cords have a widely application. Where the need for the optical fiber connection, where you need fiber optic patch cords.

Fiber Patch Cords have a widely application. Where the need for the optical fiber connection, where you need fiber optic patch cords.

Testing Equipment

FTTX+ LAN

Optical Fiber CATV

Optical Communication System

Telecommunication

SOPTO Products

- Fiber Optic Transceiver Module

- High Speed Cable

- Fiber Optical Cable

- Fiber Optical Patch Cords

- Splitter CWDM DWDM

- PON Solution

- FTTH Box ODF Closure

- PCI-E Network Card

- Network Cables

- Fiber Optical Adapter

- Fiber Optical Attenuator

- Fiber Media Converter

- PDH Multiplexers

- Protocol Converter

- Digital Video Multiplexer

- Fiber Optical Tools

- Compatible

Related Products

Performance Feature

Good Water-proof

Low insertion loss;

low reflection loss;

Stability, good repeatability;

High-precision ceramic ferrule;

Compatible with NTT standard;

Precision Grinding and fully testing;

Compliance with international standards

Patch Cord Knowledge

Recommended

Inspection and Cleaning are Critical

Clean fiber optic components are a requirement for quality connections between fiber optic equipment. One of the most basic and important procedures for the maintenance of fiber optic systems is to clean the fiber optic equipment.

Any contamination in the fiber connection can cause failure of the component or failure of the whole system. Even microscopic dust particles can cause a variety of problems for optical connections. A particle that partially or completely blocks the core generates strong back reflections, which can cause instability in the laser system. Dust particles trapped between two fiber faces can scratch the glass surfaces. Even if a particle is only situated on the cladding or the edge of the endface, it can cause an air gap or misalignment between the fiber cores which significantly degrades the optical signal.

- A 1-micrometer dust particle on a single-mode core can block up to 1% of the light (a 0.05dB loss).

- A 9-micrometer speck is still too small to see without a microscope, but it can completely block the fiber core. These contaminants can be more difficult to remove than dust particles.

By comparison, a typical human hair is 50 to 75 micrometers in diameter, as much as eight times larger. So, even though dust might not be visible, it is still present in the air and can deposit onto the connector. In addition to dust, other types of contamination must also be cleaned off the endface. Such materials include:

- Oils, frequently from human hands

- Film residues, condensed from vapors in the air

- Powdery coatings, left after water or other solvents evaporate away

These contaminants can be more difficult to remove than dust particles and can also cause damage to equipment if not removed.

Caution: With the high powered lasers now in use for communications systems, any contaminant can be burned into the fiber endface if it blocks the core while the laser is turned on. This burn might damage the optical surface enough that it cannot be cleaned.

When you clean fiber components, always complete the steps in the procedures carefully. The goal is to eliminate any dust or contamination and to provide a clean environment for the fiber-optic connection. Remember that inspection, cleaning and re-inspection are critical steps which must be done before you make any fiber-optic connection.

Related Read: