-

- Sopto Home

-

- Special Topic

-

- Patch Cord Knowledge

-

- Best Practice for Fiber Cabling

Patch Cord Knowledge

- Fiber Optic Connector Ferrule Design

- Fiber Optic Connector Design

- E2000 to ST Fiber Patch Cable Overview

- Acceptable and Unacceptable Fiber Connector End-Face Finishes

- Using Wipes and Cleaning Cassettes to Clean Fiber Patch Cords

- Not-Too-Tight Mating of Fiber Optic Connectors

- Matching Gel and Oils Contamination about Fiber Optic Connectors

- The Effect of Improper Use of Fiber Optic Connectors

- Why Fiber Optic Connectors are Fragile?

SOPTO Special Topic

Certificate

Guarantee

Except products belongs to Bargain Shop section, all products are warranted by SOPTO only to purchasers for resale or for use in business or original equipment manufacturer, against defects in workmanship or materials under normal use (consumables, normal tear and wear excluded) for one year after date of purchase from SOPTO, unless otherwise stated...

Return Policies

Defective products will be accepted for exchange, at our discretion, within 14 days from receipt. Buyer might be requested to return the defective products to SOPTO for verification or authorized service location, as SOPTO designated, shipping costs prepaid. .....

Applications

Fiber Patch Cords have a widely application. Where the need for the optical fiber connection, where you need fiber optic patch cords.

Fiber Patch Cords have a widely application. Where the need for the optical fiber connection, where you need fiber optic patch cords.

Testing Equipment

FTTX+ LAN

Optical Fiber CATV

Optical Communication System

Telecommunication

SOPTO Products

- Fiber Optic Transceiver Module

- High Speed Cable

- Fiber Optical Cable

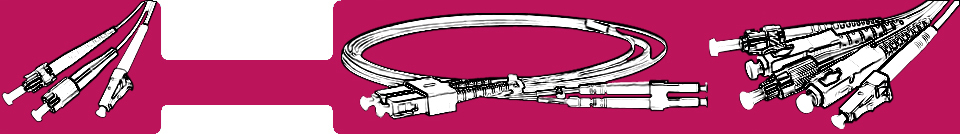

- Fiber Optical Patch Cords

- Splitter CWDM DWDM

- PON Solution

- FTTH Box ODF Closure

- PCI-E Network Card

- Network Cables

- Fiber Optical Adapter

- Fiber Optical Attenuator

- Fiber Media Converter

- PDH Multiplexers

- Protocol Converter

- Digital Video Multiplexer

- Fiber Optical Tools

- Compatible

Related Products

Performance Feature

Good Water-proof

Low insertion loss;

low reflection loss;

Stability, good repeatability;

High-precision ceramic ferrule;

Compatible with NTT standard;

Precision Grinding and fully testing;

Compliance with international standards

Patch Cord Knowledge

Recommended

Best Practice for Fiber Cabling

The principles of good management for fiber cords are similar to those for copper. However, there are special considerations with optical fiber, and extra care is needed in some areas.

Planning

Administration activities (MAC’s) are initiated with a change request. The change request must contain all necessary information to begin the planning process. (See General Management section below)

Searching the Records

Once a request form is received, search the records to be sure of the circuit path. The floor plans provided by the system designer should show backbone/riser cables, TRs/FDs and lOs. Any changes or additions made since your cabling infrastructure was installed should also have been documented. If the records are stored in a database, a different screen can be displayed for each user. This screen should supply you with the information you need, including the riser and horizontal fiber pairs serving the particular WAO and the locations of available fiber.

Check Design Guidelines and Match Cords

Make sure you know the specifications and design of your fiber cabling. Ensure you have patch cords matched to the installed cabling, since optical fiber cords of different types should not be mixed.

Efficient Routing

The first step in choosing a cord of the correct length is to determine the best route between its points of connection.

This is usually the shortest route through horizontal and vertical cable pathways that does not obstruct or interfere with other cords and connectors on the panel. Avoid running cords through cable pathways that are already congested.

Vertical and Horizontal Sizing

Having established the best route for the cord, find the required length by adding the horizontal and vertical distances.

Minimizing Slack

When selecting a cord to make a cross connection, avoid excessive slack and provide a neat appearance.

Tight cords will pull on connectors and too much slack complicates cord management, making the panel more difficult to work on.

Efficient Management

Ensure you have cords of the right length available and that panels are fitted with correct cable management accessories.

In general, a horizontal patch cord management guide is needed for every two rack units, depending on the type of optical patch panel or lightguide interconnect unit (LIU).

At the optical patch panel or LIU, route patch cords equally toward both sides of the vertical cable management channels to prevent overloading one side.

Maintaining Old with New

Take care not to mix up cords of different core diameters. Additionally, cords must be of the same or higher bandwidth as the behind-the-wall cabling. System performance regarding distances cannot be guaranteed if lower rated patch cords are used. Color-coding of connectors for different fiber standards make it easy to avoid confusion.

Core Diameter

Fiber patch cords must use the same core diameter as the trunk cable. A large attenuation penalty will occur when using a 62.5µm patch cord with a 50µm trunk cable fiber or vice versa. Single mode fiber patch cords should use fiber with the same Mode Field Diameter as the trunk cable fiber.

Factory-terminated vs. Field-polished

Factory-terminated cords guarantee fiber patches with optimum performance. Field polished cords are not covered by warranties and are likely to deliver lower performance and variable quality.

Fiber Safety Precautions and Responsibilities

The lasers that carry information through fiber cables may cause irreparable damage to the retina. Always avoid looking directly into an energized optical fiber, and never attach a microscope or other magnifying device to an energized optical fiber. Always wear appropriate eye protection and ensure that unused ports are covered.

Preparation

To minimize disconnect time, do as much preparation as possible before performing administration activities.

Study Administrative Records

Locate the ports that must be connected or reconnected. Ensure technicians have clear information on what they need to do, including labeling information for the ports involved.

Cord Inspection

It is essential to ensure cords are of the right type and quality, and that they are clean and in good condition.

Fiber patch cords should be inspected for physical damage including:

• stress marks from bending on the sheath

• pullout of fibers from the connector

• cracks or scratches on fiber end in connector using a fiber examination microscope

Cleanliness is vital in fiber optic connections so special care is needed with:

• connector ends on patch cords

• connector ends on panels

• connector ends on network equipment

For detailed information on how to clean ST, SC, LC and MPO connectors see APPENDIX A. Materials that will be needed include:

• cassettes for connector ends

• lint-free wipes

• cleaning stick for behind the wall (BTW) MPOs

Patching

Once work on a panel is started, it should be completed without delay using best practice at each stage.

Cord Handling

Kinks, snags, pinches and poor contacts can dramatically reduce the performance of a fiber patch cord. The following factors are important in avoiding these problems.

Bend Radius

The minimum bend radius for optical fiber patch cords varies with cord diameter. For 1.6 mm and 3.0 mm cords the minimum un-loaded bend radius is 1.4 in (3.5 cm), and for InstaPATCH plus MPO patch cords, the minimum bend radius is ten times the cord diameter. Exceeding the bend radius can result in significant additional loss and adverse impact on channel performance.

Cord Pulling and Stress

Be careful not to use excessive force during the patching process. This can stress cords and connectors, reducing their performance. If you need to use force in pulling a cord, something is wrong. Find the problem and fix it before proceeding.

Bundling

Bundling and tying cords gives the panel a neat appearance but tight bundling increases the risk of pinching. Do not tighten ties beyond the point where individual cords can rotate freely. Use only products manufactured for this purpose, and consider the use of products that can be re-used without the use of tools such as “hook and loop” strapping.

Routing Cords Through Cable Pathways

If the existing cord is the right length, it may be possible to re-use it. If this is the case, remove the cord completely and re-run it in through the cable pathways. This is the only sure way to ensure there are no tangles, kinks or strains in the cord.

Steps in Removing and Adding Cords

Removing a patch cord

1. Locate the existing circuit on both fields of the TR/FD or equipment room (ER)

2. Unplug the patch cord at one end and cover the connector end face(s) with a dust cap

3. Cover the open port with a dust cover - some adapter ports have spring-loaded covers that automatically cover the port

4. Gently lift the cord straight up, taking up slack until its movement is detected

5. Follow the cord routing, gently removing it along its length from the cable pathways

6. Find the other end and unplug it

7. Fully remove the cord

Adding a patch cord

1. Identify the location of the new circuit

2. Plug one end of the patch cord into the fiber coupling

3. Route the patch cord

4. At the field nearest to the switch and/or computer port field, locate the new connecting point

5. Plug the other end of the patch cord into the fiber coupling

Validation

Final Visual Inspection and Panel Closure

Patching must be right first time since mistakes can cause costly disruption and re-work. The time taken to make a final visual check on connections is a good investment. When patch panels are mounted in enclosures, ensure these are securely closed and, where necessary, locked, making sure that cord slack is not snagged or pinched by the doors.

Update Documentation

The final step is to update the documentation to the as-built configuration and close the work order associated with the completed change request.

Related Knowledge: