-

- Sopto Home

-

- Special Topic

-

- Patch Cord Knowledge

-

- Choose Suitable Patch Panels for Cable Management

Patch Cord Knowledge

- Fiber Optic Connector Ferrule Design

- Fiber Optic Connector Design

- E2000 to ST Fiber Patch Cable Overview

- Acceptable and Unacceptable Fiber Connector End-Face Finishes

- Using Wipes and Cleaning Cassettes to Clean Fiber Patch Cords

- Not-Too-Tight Mating of Fiber Optic Connectors

- Matching Gel and Oils Contamination about Fiber Optic Connectors

- The Effect of Improper Use of Fiber Optic Connectors

- Why Fiber Optic Connectors are Fragile?

SOPTO Special Topic

Certificate

Guarantee

Except products belongs to Bargain Shop section, all products are warranted by SOPTO only to purchasers for resale or for use in business or original equipment manufacturer, against defects in workmanship or materials under normal use (consumables, normal tear and wear excluded) for one year after date of purchase from SOPTO, unless otherwise stated...

Return Policies

Defective products will be accepted for exchange, at our discretion, within 14 days from receipt. Buyer might be requested to return the defective products to SOPTO for verification or authorized service location, as SOPTO designated, shipping costs prepaid. .....

Applications

Fiber Patch Cords have a widely application. Where the need for the optical fiber connection, where you need fiber optic patch cords.

Fiber Patch Cords have a widely application. Where the need for the optical fiber connection, where you need fiber optic patch cords.

Testing Equipment

FTTX+ LAN

Optical Fiber CATV

Optical Communication System

Telecommunication

SOPTO Products

- Fiber Optic Transceiver Module

- High Speed Cable

- Fiber Optical Cable

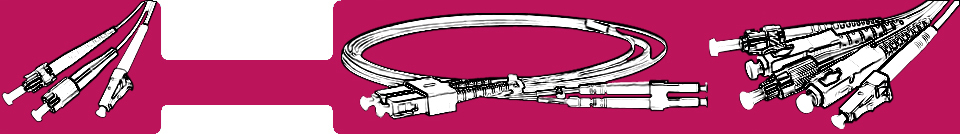

- Fiber Optical Patch Cords

- Splitter CWDM DWDM

- PON Solution

- FTTH Box ODF Closure

- PCI-E Network Card

- Network Cables

- Fiber Optical Adapter

- Fiber Optical Attenuator

- Fiber Media Converter

- PDH Multiplexers

- Protocol Converter

- Digital Video Multiplexer

- Fiber Optical Tools

- Compatible

Related Products

Performance Feature

Good Water-proof

Low insertion loss;

low reflection loss;

Stability, good repeatability;

High-precision ceramic ferrule;

Compatible with NTT standard;

Precision Grinding and fully testing;

Compliance with international standards

Patch Cord Knowledge

Recommended

Choose Suitable Patch Panels for Cable Management

When surmounting trouble rises, a fiber optic technician must choose the most suitable patch panel for a particular situation. He or she must recognize that when it comes to easy installation, proper termination and long-term maintenance, not every patch panels are made equally.

Optical fiber is robust and for that reason deserves some kind of special treatment. For instance, if your horizontal copper cable is broken, one user is going to be affected. If your backbone fiber goes down, it will take a lot of users down by using it.

For this reason using fully enclosed connecting hardware for optical fiber is vital. This is when the technician must choose between using wall-mounted or rack-mounted hardware. The optical fiber density required will likely influence the technician’s choice between the wall-mounted and rack-mounted connectivity. Many technicians will choose to use fiber patch cables. Believe in technician to know notebook computer.

Wall-mounted enclosures are compatible with as much as 24 optical fibers. However with small form factors and high density connectors, wall-mounted enclosures can extend the fiber optic cable count to as much as 144. Wall-mount enclosures offer the benefit of reduced floor space requirements. Rack-mounted optical fiber enclosures can be used with higher fabric counts or with respect to the proximity to communications equipment, where rack-mounted optical fiber enclosures are preferable. 1U enclosures can handle as much as 24 optical fiber cables with ST or SC connectors or up to 48 optical fibers by using small form factor connectors.

For added protection, 2U to 4U enclosures may be used to handle as much as 144 optical fiber connections. A 12 fiber MPO connector can speed installation some time and increase the power of connection hardware. The factory terminated and tested cassettes take care of breaking out the optical fibers in the MPO connectors to ST, SC, or MT-RJ connectors. The MPO cassettes can double the amount concentration that are possible in rack-mount enclosures Up to 72 optical fibers inside a 1U enclosure and 288 optical fibers in a 4U enclosure – making these optical fibers perfectly fit to meet high density applications, for example data centers and storage area networks.

MPO fiber optic cassette, with SC, LC, ST, or FC connectors, is really a highly flexible fiber management unit that can be used standalone or integrated into the MPO fiber optic patch panels. Accessibility is an issue for very long term maintenance when selecting a rack-mount enclosure. The 1U enclosures may have a an access panel to reach the rear optical fibers, while larger enclosures could have a removable rear cover with adequate room inside to create changes or perform repairs. Strain relief and loop management for incoming cables must be provided, nonetheless management devices ought to be sufficiently small in order to not interfere with accessibility optical fibers.

Cable management for patch cords ought to be provided on the front from the enclosure with clear front covers and labeling arranged to ease moves, adds and changes by making certain port identification is not obscured by patch cords. Since copper patch panels have to be sufficiently strong not to flex too much as the cables are punched down. The rolled edges on the panel sheet metal stock help make the panels rigid. Copper patch panels ought to provide 24 ports in a 1U height or 48 ports in a 2U height. It’s very important to make sure that the modular jacks and circuit traces on the panels are protected from debris that can short out circuits. All cable management systems must be simple to use and maintain to prevent any potential issues.

If you would like to purchase our optical patch cables and patch panels, please contact a Sopto representative by calling 86-755-36946668, or by sending an email to info@sopto.com. For more info, please browse our website.