-

- Sopto Home

-

- Special Topic

-

- Fiber Optics knowledge

-

- Preparation before Striping and Cleaning Indoor Fiber-Optics Cab

Fiber Optics knowledge

- Maintained Methods of Fusion Splicer Parts

- How to Use the Fiber Optic Cleaver?

- What are Fixed Attenuators & Variable Attenuators?

- Deployable Fiber Optic Systems for Harsh Mining Environments

- Developing Miniature Fiber Optic Cable Has Become the Trend

- Fiber Optic Cleaning Procedures

- 6 Steps to Selecting a Fiber Optic Cable

- Signal Attenuation Introduction

- How Fiber Transmission Works?

SOPTO Special Topic

Certificate

Guarantee

Except products belongs to Bargain Shop section, all products are warranted by SOPTO only to purchasers for resale or for use in business or original equipment manufacturer, against defects in workmanship or materials under normal use (consumables, normal tear and wear excluded) for one year after date of purchase from SOPTO, unless otherwise stated...

Return Policies

Defective products will be accepted for exchange, at our discretion, within 14 days from receipt. Buyer might be requested to return the defective products to SOPTO for verification or authorized service location, as SOPTO designated, shipping costs prepaid. .....

Applications

Fiber Optis can be used in so many fields:

Data Storage Equipment

Interconnects,Networking

Gigabit Ethernet

FTTx, HDTV,CATV

Aerospace & Avionics

Data Transfer Tests

Network Equipment

Broadcast Automotive

Electronics,Sensing

Oil & Gas, Imaging

Outside Plant,Central Office

Harsh Environment

Data Transmission

Illumination,Institutions

Ship to Shore,Education

Simulation,Military,Space

Unmanned Aerial Vehicles

Semiconductor Equipment

Diagnostics & Troubleshooting

Premise Networks Carrier Networks

Independent Telecommunication Providers

SOPTO Products

- Fiber Optic Transceiver Module

- High Speed Cable

- Fiber Optical Cable

- Fiber Optical Patch Cords

- Splitter CWDM DWDM

- PON Solution

- FTTH Box ODF Closure

- PCI-E Network Card

- Network Cables

- Fiber Optical Adapter

- Fiber Optical Attenuator

- Fiber Media Converter

- PDH Multiplexers

- Protocol Converter

- Digital Video Multiplexer

- Fiber Optical Tools

- Compatible

Performance Feature

Fiber Optics knowledge

Recommended

Preparation before Striping and Cleaning Indoor Fiber-Optics Cable

To strip and clean indoor FO cable preparation, follow this procedure.

Step 1: Decide how much cable you want in the termination cabinet, so you know how much jacket to remove at the slack end. Mark the jacket. Be sure you allow enough length. Some like to put a piece of shrink sleeve, about 2 in. or 3 in. long, over this point in the cable. These are available with your cable identification imprinted on them.

Step 2: Put a circular score around the outer jacket at 7 in. to 10 in. away from the cable's end. Be careful not to cut through the jacket and cut off the ripcord. Strip back and remove the 7-in. to 10-in. long piece of outer jacket to expose the ripcord, which you'll use to remove the rest of the jacket to the Step 1 mark. Make sure you have enough length on the ripcord to get a good grip. You can use a knife with a hook blade or one of a variety of other outer jacket cutters.

Generally, the jacket's outer part of the plastic is soft, and the inner part is hard or brittle. So, you should be able to bend the jacket, and the plastic will break off.

Step 3: Score the cable at the Step 1 mark, being careful not to cut through the jacket.

Step 4: Strip the jacket down to the mark with the ripcord, and remove it from the cable. Your best bet is to put a little nick in the jacket at the ripcord's location with the hook blade knife. This provides a good starting location for the ripcord and reduces the possibility of it breaking.

Step 5: Remove the outer jacket from the point where it will enter the termination cabinet to the slack end, making sure you leave a few inches of the jacket in the enclosure. Use cable ties to fasten the cable to a fastening part inside the enclosure.

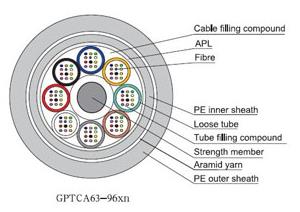

Step 6: If the buffered fibers are in a sub-group jacket, you'll have to remove this, too, again making sure you don't cut too deeply through the jacket. If there are no sub-groups, just individual buffered fibers, unwrap them from around the strength member.

Step 7: Cut the strength member to length, and fasten it solidly to the enclosure. This will prevent the cable from pulling out of the enclosure and putting damaging strain on the fibers. If the strength member is a solid fiberglass rod, you may have to use a set-screw lug to attach it to the enclosure. If it is aramid yarn, then fasten it to the enclosure by wrapping it around a screw (manufacturers' recommendation). This writer finds crimping it in a lug is neater and more secure.

For more high quality and low cost fiber optics, please contact SOPTO.

Related Knowledge:

FTTX Drop Cable Construction Methods

Quality Control in Optical Fiber Production

China FTTH fiber optic splicing best method

Steps for terminating fiber optic cable using epoxy