-

- Sopto Home

-

- Special Topic

-

- Fiber Optics knowledge

-

- China FTTH fiber optic splicing best method

Fiber Optics knowledge

- Maintained Methods of Fusion Splicer Parts

- How to Use the Fiber Optic Cleaver?

- What are Fixed Attenuators & Variable Attenuators?

- Deployable Fiber Optic Systems for Harsh Mining Environments

- Developing Miniature Fiber Optic Cable Has Become the Trend

- Fiber Optic Cleaning Procedures

- 6 Steps to Selecting a Fiber Optic Cable

- Signal Attenuation Introduction

- How Fiber Transmission Works?

SOPTO Special Topic

Certificate

Guarantee

Except products belongs to Bargain Shop section, all products are warranted by SOPTO only to purchasers for resale or for use in business or original equipment manufacturer, against defects in workmanship or materials under normal use (consumables, normal tear and wear excluded) for one year after date of purchase from SOPTO, unless otherwise stated...

Return Policies

Defective products will be accepted for exchange, at our discretion, within 14 days from receipt. Buyer might be requested to return the defective products to SOPTO for verification or authorized service location, as SOPTO designated, shipping costs prepaid. .....

Applications

Fiber Optis can be used in so many fields:

Data Storage Equipment

Interconnects,Networking

Gigabit Ethernet

FTTx, HDTV,CATV

Aerospace & Avionics

Data Transfer Tests

Network Equipment

Broadcast Automotive

Electronics,Sensing

Oil & Gas, Imaging

Outside Plant,Central Office

Harsh Environment

Data Transmission

Illumination,Institutions

Ship to Shore,Education

Simulation,Military,Space

Unmanned Aerial Vehicles

Semiconductor Equipment

Diagnostics & Troubleshooting

Premise Networks Carrier Networks

Independent Telecommunication Providers

SOPTO Products

- Fiber Optic Transceiver Module

- High Speed Cable

- Fiber Optical Cable

- Fiber Optical Patch Cords

- Splitter CWDM DWDM

- PON Solution

- FTTH Box ODF Closure

- PCI-E Network Card

- Network Cables

- Fiber Optical Adapter

- Fiber Optical Attenuator

- Fiber Media Converter

- PDH Multiplexers

- Protocol Converter

- Digital Video Multiplexer

- Fiber Optical Tools

- Compatible

Performance Feature

Fiber Optics knowledge

Recommended

China FTTH fiber optic splicing best method

Pigtail type fiber optic mechanical splice is China FTTH fiber optic splicing best method.

With the industry gradually clear understanding on the triple play, the construction of the fiber-optic network is rapidly carried out, competition is fiercer. Especially China Telecom recently dished started "Broadband China, Optical Network City" project. This year fiber to the home increase in a great amount, total will reach ten million level, but there are many problems occur which should be think over behind this huge market demand.

Due to our vast territory, large population, the situation and conditions vary in different places, so the FTTH program or product features will be different. Due to a large number of non-standard fiber optic cable laying before, so it need special requirement for fiber splicing products, for example as follows:

- core diameter deviation + splicing performance;

- core brittle change + the stability of the splicing stability performance;

- poor quality cable tape resulting in core loose+ pigtail redundant cabling requirements when distribute;

- roll cable, pull back cable core;

- second-hand material produced cable jacket when vertical laying or high-temperature environment and pigtail redundant requirements when pull back the core;

- Cable jacket dimension + the tensile performance requirements

U.S. A. 3M earliest introduce this products in the domestic market. 3 years ago, the on-site connector price is about 120RMB. Since the factory established in Shanghai, the price is reduced to 40RMB at present.

After Japan's Sumitomo and Nanjing Putian (POTEVIO) setted up the S & P Company to produce on-site connector, price reduces to about 30RMB.

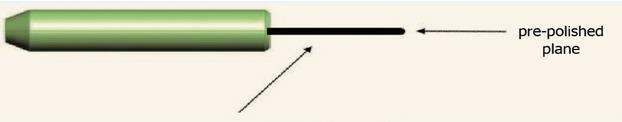

One of the reasons for some company to lower price is lower domestic production and labor cost, but the most important is the lower quality of the product technology, that is the Embedded fiber end face production performance. Before, use spherical - plane connecting technology, pre-set fiber point use fiber grinding spherical, splicing performance not totally dependent on matching oil. while now use the shear plane - Live shear plane technology, pre-set fiber point use factory shear plane, splicing performance is entirely dependent on matching liquid, equivalent to the shortened fiber optic patch cord + splice mode. As shown in Figure 1.

Figure1

Prepared requirements of filed connector pro-embedded fiber point

Welding on-site connector made by Sumitomo Japan, Nisshin South Korea is commonly known as "hot melt head".

Due to saturation of the Japanese fiber splice market, this program primarily used in some places of South Korea.

Except fusion splicer, it also should equipped the special connector housing by the factory, also need special fiber optic cable. Korea use 0.9 mm coating is high strength, good ruled, it can tolerate complicated operation and good cable jacket clamping force. In China, the drop cable inner 0.25mm costing is fragile, after splicing, the pigtail fiber will be broken if reciprocating bending during distribution or usage, and it may bring a lot of risks to FTTH project.

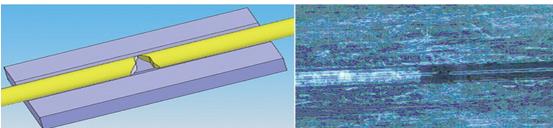

Field connector only need to prepare a fiber, but mechanical splice need two fibers, as shown in Figure 2,high strength construction, end face quality field sheared are often worse than the factory-prepared optical fiber, the splice performance entirely dependent matching fluid; mechanical splice can only fix 0.25~0.9mm coating layer, the fastening force is less than 10 N, cannot reach FTTH on-site project requirements, therefore field assembly connector become the mainstream, also become the main program products instead of splicing products.

Figure2

Two fiber endface on site made in mechanical splicing point

Sopto cold splicing sub-package technology (as shown in Figure 3), made the drop cable and drop cable pigtail spliced and packed in the factory ahead of time, on the filed, only need to strip the drop cable coating and preparation, splicing only need 10s. The tensile strength is greater than 10 kg, can check splicing quality through optical detection to facilitate troubleshooting.

Figure3

Pigtail Type Mechanical Splice

Use metal V-groove, splice guide quasi-surface precision and finish are much higher than the plastic continuation scraping, not easy scraping, and splice performance as much as similar foreign products. The plastic slider pinch the optical fiber in the metal V-shaped groove, the frictional force of the plastic slider ensure that when the metal V-shaped groove elongate in the high-temperature, it will not increase the space of the optical fiber splice point. Accessibility wears fiber technology, simple continuation and high success rate.

Use innovative puzzle-sealing box technology, after fiber snapping, press the puzzle cover in till the floating block deformed so as to make sure the fiber splice point in the middle of metal V-groove and floating blocks and sealed isolated with the outside world. It does not protect the splice point, but also blocked the erosion of external contamination. Water immersion test for 6 months, the loss deterioration amount is less than 0.2 dB.

Settled matching fluid chamber and the V-groove splice point connected together guarantee 30 years or even longer life connection. Factory pre-wired fiber pigtail cut end surface is pre-polished, which ensures good and persistent splice performance. Pigtails and fiber optic drop cable fixed use patented clamping technology; pull-off force is greater than 10 kg. On site only need to prepare drop cable; splice clamping time is not more than 10 s.

Splitter → splitter pigtail + adapter + yellow cable, pigtailed Splice→drop cable→drop cable pigtail type mechanical splice + ONU, as shown in Figure 5.

Figure 5

.jpg)

Pigtail Type Mechanical Splice Household Program (FTTH Program)

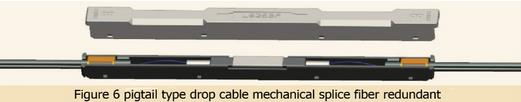

The product is suitable for the varying quality domestic fiber optic cable, when redundant fiber retracted in mechanical splice package box it can release and prevent it from pulled off; improve the suitability, as shown Figure 6. Factory prefabricated pigtails by polished ensure connection quality, also reducing reliance on matching fluid and reduce operation and maintenance costs; It can be reused many times, on the site connecting accidentally the core broke or dirt things go into, user can remove it, then penetrate the long fiber to clean it, save cost. Fully use card pressure fix technology, no need special tools, you can ensure the fixation strength of the fiber optic cable reach 10 kg.

Figure 5

Pigtail Type Drop Cable Mechanical Splice Fiber Redundant

For more high quality and low cost fiber optics, please contact SOPTO.

Related Knowledge:

What is a Fiber Optic Patch Panel?

FTTX Drop Cable Construction Methods

Quality Control in Optical Fiber Production

Optical Fiber Cable General Cabling Guidelines

Comparison between Mechanical Splicing and Fusion Splicing