-

- Sopto Home

-

- Special Topic

-

- Fiber Optics knowledge

-

- Comparison between Mechanical Splicing and Fusion Splicing

Fiber Optics knowledge

- Maintained Methods of Fusion Splicer Parts

- How to Use the Fiber Optic Cleaver?

- What are Fixed Attenuators & Variable Attenuators?

- Deployable Fiber Optic Systems for Harsh Mining Environments

- Developing Miniature Fiber Optic Cable Has Become the Trend

- Fiber Optic Cleaning Procedures

- 6 Steps to Selecting a Fiber Optic Cable

- Signal Attenuation Introduction

- How Fiber Transmission Works?

SOPTO Special Topic

Certificate

Guarantee

Except products belongs to Bargain Shop section, all products are warranted by SOPTO only to purchasers for resale or for use in business or original equipment manufacturer, against defects in workmanship or materials under normal use (consumables, normal tear and wear excluded) for one year after date of purchase from SOPTO, unless otherwise stated...

Return Policies

Defective products will be accepted for exchange, at our discretion, within 14 days from receipt. Buyer might be requested to return the defective products to SOPTO for verification or authorized service location, as SOPTO designated, shipping costs prepaid. .....

Applications

Fiber Optis can be used in so many fields:

Data Storage Equipment

Interconnects,Networking

Gigabit Ethernet

FTTx, HDTV,CATV

Aerospace & Avionics

Data Transfer Tests

Network Equipment

Broadcast Automotive

Electronics,Sensing

Oil & Gas, Imaging

Outside Plant,Central Office

Harsh Environment

Data Transmission

Illumination,Institutions

Ship to Shore,Education

Simulation,Military,Space

Unmanned Aerial Vehicles

Semiconductor Equipment

Diagnostics & Troubleshooting

Premise Networks Carrier Networks

Independent Telecommunication Providers

SOPTO Products

- Fiber Optic Transceiver Module

- High Speed Cable

- Fiber Optical Cable

- Fiber Optical Patch Cords

- Splitter CWDM DWDM

- PON Solution

- FTTH Box ODF Closure

- PCI-E Network Card

- Network Cables

- Fiber Optical Adapter

- Fiber Optical Attenuator

- Fiber Media Converter

- PDH Multiplexers

- Protocol Converter

- Digital Video Multiplexer

- Fiber Optical Tools

- Compatible

Performance Feature

Fiber Optics knowledge

Recommended

Comparison between Mechanical Splicing and Fusion Splicing

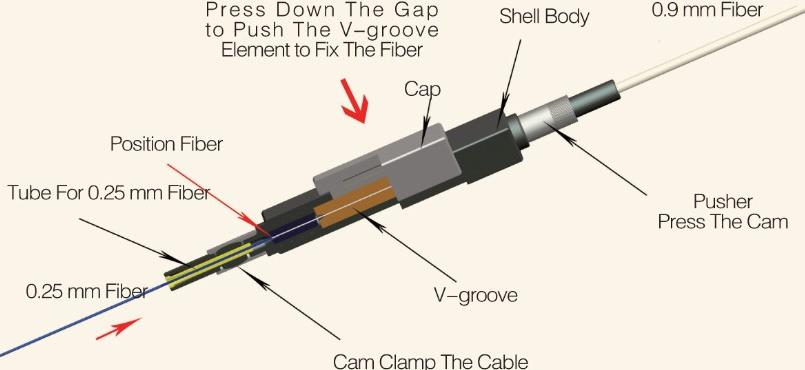

Mechanical Splicing:

Mechanical splices are simply alignment devices, designed to hold the two fiber ends in a precisely aligned position thus enabling light to pass from one fiber into the other. (Typical loss: 0.3 dB)

Fusion Splicing:

In fusion splicing a machine is used to precisely align the two fiber ends then the glass ends are "fused" or "welded" together using some type of heat or electric arc. This produces a continuous connection between the fibers enabling very low loss light transmission. (Typical loss: 0.1 dB)

Core mechanical splice structure

Which method is better?

The typical reason for choosing one method over the other is economics. Mechanical splicing has a low initial investment ($1,000 - $2,000) but costs more per splice ($12-$40 each). While the cost per splice for fusion splicing is lower ($0.50 - $1.50 each), the initial investment is much higher ($15,000 - $50,000 depending on the accuracy and features of the fusion splicing machine being purchased). The more precise you need the alignment (better alignment results in lower loss) the more you pay for the machine.

As for the performance of each splicing method, the decision is often based on what industry you are working in. Fusion splicing produces lower loss and less back reflection than mechanical splicing, because the resulting fusion splice points are almost seamless. Fusion splices are used primarily with single mode fiber, where Mechanical splices work with both single and multi-mode fiber.

Many Telecommunications and CATV companies invest in fusion splicing for their long haul single mode networks, but will still use mechanical splicing for shorter, local cable runs. Since analog video signals require minimal reflection for optimal performance, fusion splicing is preferred for this application as well. The LAN industry has the choice of either method, as signal loss and reflection are minor concerns for most LAN applications.

For more high quality and low cost fiber optics, please contact SOPTO.

Related Knowledge:

How to Choose fiber optic Cables?

How to Strip and Clean Fiber-Optic Cable?

What is Optical Fiber Composite Low-Voltage Cable?