-

- Sopto Home

-

- Special Topic

-

- Fiber Optics knowledge

-

- Optical fiber’s Raw Materials

Fiber Optics knowledge

- Maintained Methods of Fusion Splicer Parts

- How to Use the Fiber Optic Cleaver?

- What are Fixed Attenuators & Variable Attenuators?

- Deployable Fiber Optic Systems for Harsh Mining Environments

- Developing Miniature Fiber Optic Cable Has Become the Trend

- Fiber Optic Cleaning Procedures

- 6 Steps to Selecting a Fiber Optic Cable

- Signal Attenuation Introduction

- How Fiber Transmission Works?

SOPTO Special Topic

Certificate

Guarantee

Except products belongs to Bargain Shop section, all products are warranted by SOPTO only to purchasers for resale or for use in business or original equipment manufacturer, against defects in workmanship or materials under normal use (consumables, normal tear and wear excluded) for one year after date of purchase from SOPTO, unless otherwise stated...

Return Policies

Defective products will be accepted for exchange, at our discretion, within 14 days from receipt. Buyer might be requested to return the defective products to SOPTO for verification or authorized service location, as SOPTO designated, shipping costs prepaid. .....

Applications

Fiber Optis can be used in so many fields:

Data Storage Equipment

Interconnects,Networking

Gigabit Ethernet

FTTx, HDTV,CATV

Aerospace & Avionics

Data Transfer Tests

Network Equipment

Broadcast Automotive

Electronics,Sensing

Oil & Gas, Imaging

Outside Plant,Central Office

Harsh Environment

Data Transmission

Illumination,Institutions

Ship to Shore,Education

Simulation,Military,Space

Unmanned Aerial Vehicles

Semiconductor Equipment

Diagnostics & Troubleshooting

Premise Networks Carrier Networks

Independent Telecommunication Providers

SOPTO Products

- Fiber Optic Transceiver Module

- High Speed Cable

- Fiber Optical Cable

- Fiber Optical Patch Cords

- Splitter CWDM DWDM

- PON Solution

- FTTH Box ODF Closure

- PCI-E Network Card

- Network Cables

- Fiber Optical Adapter

- Fiber Optical Attenuator

- Fiber Media Converter

- PDH Multiplexers

- Protocol Converter

- Digital Video Multiplexer

- Fiber Optical Tools

- Compatible

Performance Feature

Fiber Optics knowledge

Recommended

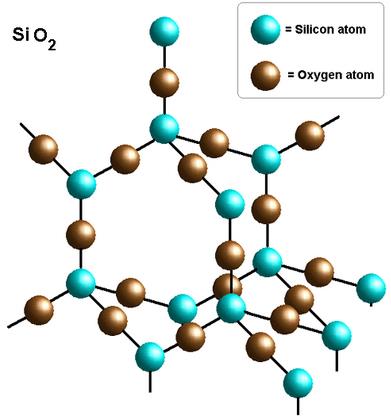

Optical fiber’s Raw Materials

Optical fibers are composed primarily of silicon dioxide (SiO 2 ), though minute amounts of other chemicals are often added. Highly purified silica powder was used in the now-outmoded crucible manufacturing method, while liquid silicon tetrachloride (SiCl 4 ) in a gaseous stream of pure oxygen (02) is the principal source of silicon for the vapor deposition method currently in widespread use.

Other chemical compounds such as germanium tetrachloride (GeCl 4 ) and phosphorus oxychloride (POC1 3 ) can be used to produce core fibers and outer shells, or claddings, with function-specific optical properties.

Silicon Dioxide Structure

Because the purity and chemical composition of the glass used in optical fibers determine the most important characteristic of a fiber—degree of attenuation—research now focuses on developing glasses with the highest possible purity.

Glasses with high fluoride content hold the most promise for improving optical fiber performance because they are transparent to almost the entire range of visible light frequencies. This makes them especially valuable for multimode optical fibers, which can transmit hundreds of discrete light wave signals concurrently.

For more high quality and low cost fiber optics, please contact SOPTO.

Related Knowledge:

How does a fiber optic cable work?

How to Choose fiber optic Cables?

Fiber Optics’ Manufacturing Method

How to Strip and Clean Fiber-Optic Cable?