-

- Sopto Home

-

- Special Topic

-

- Fiber Optics knowledge

-

- Fiber Optics’ Manufacturing Processing

Fiber Optics knowledge

- Maintained Methods of Fusion Splicer Parts

- How to Use the Fiber Optic Cleaver?

- What are Fixed Attenuators & Variable Attenuators?

- Deployable Fiber Optic Systems for Harsh Mining Environments

- Developing Miniature Fiber Optic Cable Has Become the Trend

- Fiber Optic Cleaning Procedures

- 6 Steps to Selecting a Fiber Optic Cable

- Signal Attenuation Introduction

- How Fiber Transmission Works?

SOPTO Special Topic

Certificate

Guarantee

Except products belongs to Bargain Shop section, all products are warranted by SOPTO only to purchasers for resale or for use in business or original equipment manufacturer, against defects in workmanship or materials under normal use (consumables, normal tear and wear excluded) for one year after date of purchase from SOPTO, unless otherwise stated...

Return Policies

Defective products will be accepted for exchange, at our discretion, within 14 days from receipt. Buyer might be requested to return the defective products to SOPTO for verification or authorized service location, as SOPTO designated, shipping costs prepaid. .....

Applications

Fiber Optis can be used in so many fields:

Data Storage Equipment

Interconnects,Networking

Gigabit Ethernet

FTTx, HDTV,CATV

Aerospace & Avionics

Data Transfer Tests

Network Equipment

Broadcast Automotive

Electronics,Sensing

Oil & Gas, Imaging

Outside Plant,Central Office

Harsh Environment

Data Transmission

Illumination,Institutions

Ship to Shore,Education

Simulation,Military,Space

Unmanned Aerial Vehicles

Semiconductor Equipment

Diagnostics & Troubleshooting

Premise Networks Carrier Networks

Independent Telecommunication Providers

SOPTO Products

- Fiber Optic Transceiver Module

- High Speed Cable

- Fiber Optical Cable

- Fiber Optical Patch Cords

- Splitter CWDM DWDM

- PON Solution

- FTTH Box ODF Closure

- PCI-E Network Card

- Network Cables

- Fiber Optical Adapter

- Fiber Optical Attenuator

- Fiber Media Converter

- PDH Multiplexers

- Protocol Converter

- Digital Video Multiplexer

- Fiber Optical Tools

- Compatible

Performance Feature

Fiber Optics knowledge

Recommended

Fiber Optics’ Manufacturing Processing

Many people ask how fiber optics are made. You can't just use "regular" glass. If you were to make optical fiber from ordinary window glass, the light that you shine through it would have a difficult time traveling more than a few kilometers, let alone the distances necessary for long distance transmission. That's because ordinary glass contains distortions, discolorations and other impurities that would quickly absorb, reflect, or otherwise disperse light long before it could travel any great distance.

In contrast, because optical fiber is actually made from very pure glass, the light traverses great distances largely unimpeded by impurities and distortions.

To transmit light effectively, fiber optic cable must contain glass of the highest purity. The process of making glass with this level of purity is very demanding, requiring careful control over the materials and processes involved. Yet, the fundamental concept is simple. Essentially, optical fiber is made from drawing molten fiber from a heated glass blank or "preform." The following provides a more detailed explanation of the three basic steps involved in making optical fiber.

Step1. Create the Fiber Optic Preform

A preform is a cylindrical glass blank that provides the source material from which the glass fiber will be drawn in a single, continuous strand.

Making a preform involves a chemical process known as Modified Chemical Vapor Deposition (MCVD). This process involves bubbling oxygen through various chemical solutions including germanium chloride (GeC14) and silicon chloride (SiC14).

Create the Fiber Optic Preform

The bubbling chemicals produce gas that is directed into a hollow, rotating tube made of synthetic silica or quartz. A torch is moved up and down the rotating tube, resulting in very high temperatures that cause the gas to react with oxygen to form silicon dioxide (Si02) and germanium dioxide (Ge02). These two chemicals adhere to the inside of the rotating tube where they fuse together to form extremely pure glass.

Creating the preform takes several hours, after which additional time is required for the glass blank to cool. Once cooled, the glass is tested to ensure that it meets quality standards, especially in terms of index of refraction.

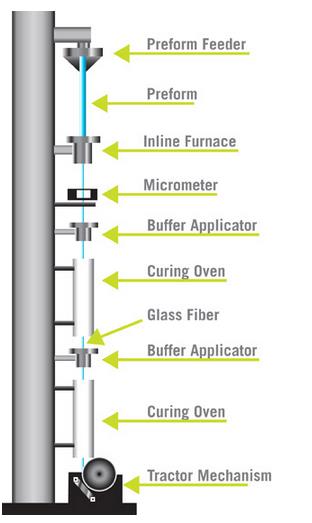

Step2. Draw Optical Fiber from the Preform

In this step, the finished glass preform is installed at the top of a tower which supports various devices used in the fiber drawing process.

The process begins by lowering one end of the preform into an in-line furnace that produces heat in a range of 3,400 to 4,000 degrees Fahrenheit. As the lower end of the preform begins to melt, it forms a molten glob that is pulled downward by gravity. Trailing behind the glob is a thin strand of glass that cools and solidifies quickly.

The equipment operator threads this glass strand through the remainder of the devices on the tower, which include a number of buffer coating applicators and ultraviolet curing ovens. Finally, the operator connects the fiber to a tractor mechanism.

The tractor device pulls the glass strand from the preform at a rate of 33 to 66 feet per second. The actual speed at which the tractor pulls the strand is dependent upon the feedback information the device receives from a laser micrometer that continually measures the fiber's diameter.

Step3. Test the Fiber Optics

The completed optical fiber must undergo a number of tests to determine the quality of the finished product. The following are a few of the assessments involved:

- Refractive index profile

- Fiber geometry inspection, including core, cladding and coating

- Tensile strength

- Bandwidth capacity

- Attenuation at different wavelengths

- Chromatic dispersion

- Operating temperature and humidity range

For more high quality and low cost fiber optics, please contact SOPTO.

Related Knowledge:

How to Fusion Splice a Fiber Optic Cable

How does Fiber Optic Cable Transmit Data?

Steps for terminating fiber optic cable using epoxy

Preparation before Striping and Cleaning Indoor Fiber-Optics Cable