-

- Sopto Home

-

- Special Topic

-

- Patch Cord Knowledge

-

- SC Fiber Optic Connector Basic Structure

Patch Cord Knowledge

- Fiber Optic Connector Ferrule Design

- Fiber Optic Connector Design

- E2000 to ST Fiber Patch Cable Overview

- Acceptable and Unacceptable Fiber Connector End-Face Finishes

- Using Wipes and Cleaning Cassettes to Clean Fiber Patch Cords

- Not-Too-Tight Mating of Fiber Optic Connectors

- Matching Gel and Oils Contamination about Fiber Optic Connectors

- The Effect of Improper Use of Fiber Optic Connectors

- Why Fiber Optic Connectors are Fragile?

SOPTO Special Topic

Certificate

Guarantee

Except products belongs to Bargain Shop section, all products are warranted by SOPTO only to purchasers for resale or for use in business or original equipment manufacturer, against defects in workmanship or materials under normal use (consumables, normal tear and wear excluded) for one year after date of purchase from SOPTO, unless otherwise stated...

Return Policies

Defective products will be accepted for exchange, at our discretion, within 14 days from receipt. Buyer might be requested to return the defective products to SOPTO for verification or authorized service location, as SOPTO designated, shipping costs prepaid. .....

Applications

Fiber Patch Cords have a widely application. Where the need for the optical fiber connection, where you need fiber optic patch cords.

Fiber Patch Cords have a widely application. Where the need for the optical fiber connection, where you need fiber optic patch cords.

Testing Equipment

FTTX+ LAN

Optical Fiber CATV

Optical Communication System

Telecommunication

SOPTO Products

- Fiber Optic Transceiver Module

- High Speed Cable

- Fiber Optical Cable

- Fiber Optical Patch Cords

- Splitter CWDM DWDM

- PON Solution

- FTTH Box ODF Closure

- PCI-E Network Card

- Network Cables

- Fiber Optical Adapter

- Fiber Optical Attenuator

- Fiber Media Converter

- PDH Multiplexers

- Protocol Converter

- Digital Video Multiplexer

- Fiber Optical Tools

- Compatible

Related Products

Performance Feature

Good Water-proof

Low insertion loss;

low reflection loss;

Stability, good repeatability;

High-precision ceramic ferrule;

Compatible with NTT standard;

Precision Grinding and fully testing;

Compliance with international standards

Patch Cord Knowledge

Recommended

SC Fiber Optic Connector Basic Structure

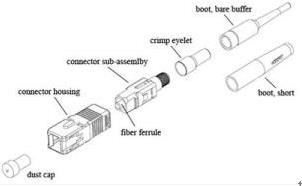

More than a dozen types of fiber optic connectors have been developed by various manufacturers since 1980s. Although the mechanical design varies a lot among different connector types, the most common elements in a fiber connector can be summarized in the following picture.

A SC Connector Sample

SC Connector Structure

Elements in a SC connector

1. The fiber ferrule.

SC Connector Fiber Ferrule

SC connector is built around a long cylindrical 2.5mm diameter ferrule, made of ceramic (zirconia) or metal (stainless alloy). A 124~127um diameter high precision hole is drilled in the center of the ferrule, where stripped bare fiber is inserted through and usually bonded by epoxy or adhesive. The end of the fiber is at the end of the ferrule, where it typically is polished smooth.

2. The connector sub-assembly body.

The ferrule is then assembled in the SC sub-assembly body which has mechanisms to hold the cable and fiber in place. The end of the ferrule protrudes out of the sub-assembly body to mate with another SC connector inside a mating sleeve (also called adapter or coupler).

3. The connector housing

Connector sub-assembly body is then assembled together with the connector housing. Connector housing provides the mechanism for snapping into a mating sleeve (adapter) and hold the connector in place.

4. The fiber cable

Fiber cable and strength member (aramid yarn or Kevlar) are crimped onto the connector sub-assembly body with a crimp eyelet. This provides the strength for mechanical handing of the connector without putting stress on the fiber itself.

5. The stress relief boot.

Stress relief boot covers the joint between connector body and fiber cable and protects fiber cable from mechanical damage. Stress relief boot designs are different for 900um tight buffered fiber and 1.6mm~3mm fiber cable.

For more info, please browse our website. For purchasing fiber optic assembly products, please contact a Sopto representative by calling 86-755-36946668, or by sending an email to info@sopto.com.