-

- Sopto Home

-

- Special Topic

-

- Patch Cord Knowledge

-

- How to Clean Fiber Optic Connectors?

Patch Cord Knowledge

- Fiber Optic Connector Ferrule Design

- Fiber Optic Connector Design

- E2000 to ST Fiber Patch Cable Overview

- Acceptable and Unacceptable Fiber Connector End-Face Finishes

- Using Wipes and Cleaning Cassettes to Clean Fiber Patch Cords

- Not-Too-Tight Mating of Fiber Optic Connectors

- Matching Gel and Oils Contamination about Fiber Optic Connectors

- The Effect of Improper Use of Fiber Optic Connectors

- Why Fiber Optic Connectors are Fragile?

SOPTO Special Topic

Certificate

Guarantee

Except products belongs to Bargain Shop section, all products are warranted by SOPTO only to purchasers for resale or for use in business or original equipment manufacturer, against defects in workmanship or materials under normal use (consumables, normal tear and wear excluded) for one year after date of purchase from SOPTO, unless otherwise stated...

Return Policies

Defective products will be accepted for exchange, at our discretion, within 14 days from receipt. Buyer might be requested to return the defective products to SOPTO for verification or authorized service location, as SOPTO designated, shipping costs prepaid. .....

Applications

Fiber Patch Cords have a widely application. Where the need for the optical fiber connection, where you need fiber optic patch cords.

Fiber Patch Cords have a widely application. Where the need for the optical fiber connection, where you need fiber optic patch cords.

Testing Equipment

FTTX+ LAN

Optical Fiber CATV

Optical Communication System

Telecommunication

SOPTO Products

- Fiber Optic Transceiver Module

- High Speed Cable

- Fiber Optical Cable

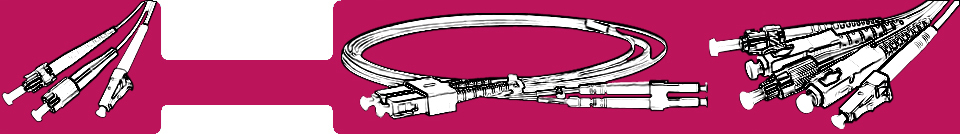

- Fiber Optical Patch Cords

- Splitter CWDM DWDM

- PON Solution

- FTTH Box ODF Closure

- PCI-E Network Card

- Network Cables

- Fiber Optical Adapter

- Fiber Optical Attenuator

- Fiber Media Converter

- PDH Multiplexers

- Protocol Converter

- Digital Video Multiplexer

- Fiber Optical Tools

- Compatible

Related Products

Performance Feature

Good Water-proof

Low insertion loss;

low reflection loss;

Stability, good repeatability;

High-precision ceramic ferrule;

Compatible with NTT standard;

Precision Grinding and fully testing;

Compliance with international standards

Patch Cord Knowledge

Recommended

How to Clean Fiber Optic Connectors?

Fiber optic cleaning is one of the most important procedures in the maintenance of fiber optic system, which need to keep the quality connections between all fiber optic equipment. As we know, the fiber optic connector consists of fiber optic plug and the adapter. The ends of the fiber optic cables are held in the core of ferrule in the plug.

Keeping the fiber end face and ferrule absolutely clean is very essential, since any particles on the end face of the fibers will cause problems such as scratching the glass surface, instability in the laser system, and a misalignment between the fiber cores, which may as a result disrupt the light transmission between the fiber optical systems.

For proper performance of the SC fiber optic cable, you must keep the SC connector clean and free of dust. Small micro-deposit of oil and dust in the canal of the connector could cause loss of light, reducing signal power and possible causing intermittent problems with the optical connections. Below picture show the part of the end face of an unclean and clean ferrule of SC connectors.

Steps to follow before the fiber optic cleaning

- Before cleaning the fiber optic connectors, make sure to disconnect the fiber optic cables from both ends and then turn off any laser source.

- Do not allow the end of the fiber optic cable to make contact with any surface including your fingers.

- Never to bend the fiber cable which will in turn cause internal breaks along the fiber and poor performance or instability.

- Using the finger cots or powder free surgical gloves to handle the fiber optic cables. Using fresh spectroscopic grade Methanol or Isopropyl Alcohol as the only cleaning solvent.

- In the daily connection work, a connector housing should be used when plugging or unplugging a fiber. A protective cap should be used to cover the unplugged fiber connectors. In the process of the fiber optic cleaning, the end face of the connector should never be touched and also the clean area of a tissue of swab should not be touched or reused.

Cleaning fiber ends

At the beginning of cleaning job, a fiber microscope should be used to inspect the fiber end, if it is contaminated as either images shows below, it should be cleaned with the dry cleaning method.

- Blow the fiber surface with a stream of Clean Dry Air (the so called CDA), which will dislodge larger, loose particles. Keep in mind and don’t tip the can of the CDA while blowing because the liquid may be released contaminant on the surface of the fiber.

- Place 1-3 drops of spectroscopic grade methanol or isopropyl alcohol in the center of a lens tissue. Do not use Acetone as a cleaning solvent on the fiber optical surfaces. Besides, to ensure the purity of the methanol or alcohol, you should never insert the lens tissue or swabs into the liguid.

- Hold the fiber by the connector. Place the wet portion of the lens tissue on the optical surface and slowly drag it across. At this step, don’t use lens paper to dry it because the dry lens paper is extremely abrasive.

- Examine the surface of the fiber under high density light using a magnifier, an optical loop, or a video inspection tool. If streaks or contaminants still remain, repeat the process using a fresh lens tissue.

- Immediately install a protective cover over the end of the cable to avoid re-contamination or insert the fiber for immediate use.

For more information, please contact a Sopto representative by calling 86-755-36946668, or by sending an email to info@sopto.com