-

- Sopto Home

-

- Special Topic

-

- Patch Cord Knowledge

-

- Fiber Optic Connector Polishing Machine Buying Guide

Patch Cord Knowledge

- Fiber Optic Connector Ferrule Design

- Fiber Optic Connector Design

- E2000 to ST Fiber Patch Cable Overview

- Acceptable and Unacceptable Fiber Connector End-Face Finishes

- Using Wipes and Cleaning Cassettes to Clean Fiber Patch Cords

- Not-Too-Tight Mating of Fiber Optic Connectors

- Matching Gel and Oils Contamination about Fiber Optic Connectors

- The Effect of Improper Use of Fiber Optic Connectors

- Why Fiber Optic Connectors are Fragile?

SOPTO Special Topic

Certificate

Guarantee

Except products belongs to Bargain Shop section, all products are warranted by SOPTO only to purchasers for resale or for use in business or original equipment manufacturer, against defects in workmanship or materials under normal use (consumables, normal tear and wear excluded) for one year after date of purchase from SOPTO, unless otherwise stated...

Return Policies

Defective products will be accepted for exchange, at our discretion, within 14 days from receipt. Buyer might be requested to return the defective products to SOPTO for verification or authorized service location, as SOPTO designated, shipping costs prepaid. .....

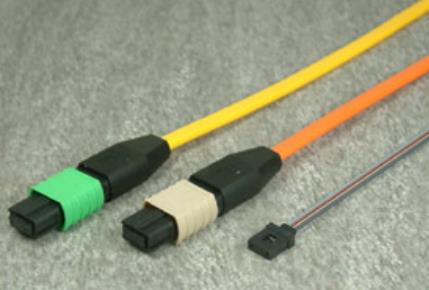

Applications

Fiber Patch Cords have a widely application. Where the need for the optical fiber connection, where you need fiber optic patch cords.

Fiber Patch Cords have a widely application. Where the need for the optical fiber connection, where you need fiber optic patch cords.

Testing Equipment

FTTX+ LAN

Optical Fiber CATV

Optical Communication System

Telecommunication

SOPTO Products

- Fiber Optic Transceiver Module

- High Speed Cable

- Fiber Optical Cable

- Fiber Optical Patch Cords

- Splitter CWDM DWDM

- PON Solution

- FTTH Box ODF Closure

- PCI-E Network Card

- Network Cables

- Fiber Optical Adapter

- Fiber Optical Attenuator

- Fiber Media Converter

- PDH Multiplexers

- Protocol Converter

- Digital Video Multiplexer

- Fiber Optical Tools

- Compatible

Related Products

Performance Feature

Good Water-proof

Low insertion loss;

low reflection loss;

Stability, good repeatability;

High-precision ceramic ferrule;

Compatible with NTT standard;

Precision Grinding and fully testing;

Compliance with international standards

Patch Cord Knowledge

Recommended

Fiber Optic Connector Polishing Machine Buying Guide

Automatic fiber connector polishing machines are required for high volume, high quality and consistent fiber connector polishing for fiber cable assembly houses. (fiber patch cable manufacturers). This buying guide will direct you to the perfect machine for your specific requirement.

The 7 Guidelines for Choosing a Fiber Connector Polishing Machine

In evaluating polishing machines, look for a machine that minimizes any variation in the polishing process. Variations lead to variations in the finish and inconsistent results. Current polishing machines are designed to eliminate variations in polishing and to achieve high-quality, consistent work.

You should do your homework before making a decision, follow these 7 steps and you won’t be too far off.

1. Can you adjust the pressure?

A fiber connector’s finished end-face geometry is produced by the combination of the loading pressure and the hardness of the polishing pad (polishing surface). In order to optimize the connector end-face, the polishing machine must have adjustable pressure setting tool with clearly marked divisions of measurement.

Look for four-corner hold-downs. Hold-down fasteners in all four corners of the connector holder evenly distribute film pressure to minimize off-center polishing. A popular alternative – using center pressure from above – allows the possibility of wiggling or vibrating the connector holder. Such motion increases the vertex offset and leads to inconsistent finishes.

The polishing film rests on a rubber polishing pad. These pads, in conjunction with the four-corner hold-downs, distribute pressure evenly across the polishing area. Because the pads are resilient, they also help to control the radius of curvature because the ferrule is pressed into the pad during polishing. Different pads (and companion spacer) are available for different styles of connectors. It is important to use the proper pad.

2. Does the machine have a timer?

Timing is very important for the connector polishing process. Each cable assembly house may try and set their own set of polishing films and times. So a settable timer is required for a pre-defined sequence of polishing steps. Typically you will find timers with a setting range from 0 to 60 seconds.

3. Can you quickly and easily change different connector holders?

Typically the connector polishing machine should be able to handle most types of fiber connectors such as SC, ST, FC, LC, MU, E2000, SMA, etc. In order to fully utilize the machine, it must be easy and quick to change different type of connector holders. This can improve the production output and lower labor cost. Also the production line is more flexible with inter-changeable connector holders.

.png)

Different Connector Holders

Precision connector holders are very critical. They should be machined to exacting tolerances so that ferrules are precisely positioned for polishing.

4. Does the machine have removable polishing platens?

Polishing platens are the mechanical part that holds the polishing films and polish against the connector end-face. If the polishing platens can be easily removed, you can minimize the chances of contamination and increase polish films’ life.

5. What is the polishing motion pattern? Is it optimized for consistent result while conserving polishing films?

Polishing motion is a very critical factor in determining connector’s end-face quality. Polishing motion is the motion of the surface that performs the polishing. This motion must guarantee a evenly balanced pressure across all sides.

Otherwise the connector will suffer deformed end-face geometry which yields out of spec products. This can significantly affect your production yield and cost. The perfect polishing motion is shown in the following figure. It should be an orbital circular oscillation motion.

.png)

Orbital Polishing

6. Can you polish APC (8° angle) connectors?

APC 8° angled polishing is a must when very low back reflection level is required such as < –65dB. The polishing machine should be able to handle PC polish including SPC and UPC as well as APC polishing. You shouldn’t be required to purchase different machines for PC and APC polish.

There are currently a new types of PC (physical contact) polish proposed, which is called MPC (Maximum Physical Contact). MPC can meet some of APC polish spec, but in most cases APC is still demanded.

.png)

Angled Physical Contact

7. Does the manufacturer have polishing recipes for different connectors?

Today’s fiber connectors must meet industry standard specifications. In order to consistently meet those performance requirements, the polishing machine vendor usually provides a proven polishing “recipes” for obtaining the connector specifications. The following table shows an example.

Four-Step Single Mode Connector Polishing Recipe

|

Step |

Description |

Polishing Film Type |

Timer Setting |

Lubrication |

|

1 |

Epoxy Removal |

15um Silicon Carbide |

10 sec |

Dry |

|

2 |

Beginning Polish |

5um Diamond |

30 sec |

DI water |

|

3 |

Intermediate Polish |

1um Diamond |

60 sec |

DI water |

|

4 |

Final Polish |

ULTRAFILM 5 |

10 sec |

DI water |

For more info, please browse our website.