-

- Sopto Home

-

- Special Topic

-

- Patch Cord Knowledge

-

- 4 Measures in Fiber Optic Fusion Splicer

Patch Cord Knowledge

- Fiber Optic Connector Ferrule Design

- Fiber Optic Connector Design

- E2000 to ST Fiber Patch Cable Overview

- Acceptable and Unacceptable Fiber Connector End-Face Finishes

- Using Wipes and Cleaning Cassettes to Clean Fiber Patch Cords

- Not-Too-Tight Mating of Fiber Optic Connectors

- Matching Gel and Oils Contamination about Fiber Optic Connectors

- The Effect of Improper Use of Fiber Optic Connectors

- Why Fiber Optic Connectors are Fragile?

SOPTO Special Topic

Certificate

Guarantee

Except products belongs to Bargain Shop section, all products are warranted by SOPTO only to purchasers for resale or for use in business or original equipment manufacturer, against defects in workmanship or materials under normal use (consumables, normal tear and wear excluded) for one year after date of purchase from SOPTO, unless otherwise stated...

Return Policies

Defective products will be accepted for exchange, at our discretion, within 14 days from receipt. Buyer might be requested to return the defective products to SOPTO for verification or authorized service location, as SOPTO designated, shipping costs prepaid. .....

Applications

Fiber Patch Cords have a widely application. Where the need for the optical fiber connection, where you need fiber optic patch cords.

Fiber Patch Cords have a widely application. Where the need for the optical fiber connection, where you need fiber optic patch cords.

Testing Equipment

FTTX+ LAN

Optical Fiber CATV

Optical Communication System

Telecommunication

SOPTO Products

- Fiber Optic Transceiver Module

- High Speed Cable

- Fiber Optical Cable

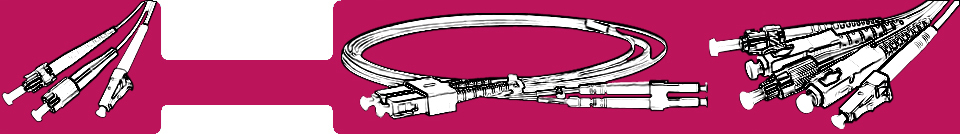

- Fiber Optical Patch Cords

- Splitter CWDM DWDM

- PON Solution

- FTTH Box ODF Closure

- PCI-E Network Card

- Network Cables

- Fiber Optical Adapter

- Fiber Optical Attenuator

- Fiber Media Converter

- PDH Multiplexers

- Protocol Converter

- Digital Video Multiplexer

- Fiber Optical Tools

- Compatible

Related Products

Performance Feature

Good Water-proof

Low insertion loss;

low reflection loss;

Stability, good repeatability;

High-precision ceramic ferrule;

Compatible with NTT standard;

Precision Grinding and fully testing;

Compliance with international standards

Patch Cord Knowledge

Recommended

4 Measures in Fiber Optic Fusion Splicer

Fiber Optic Fusion Splicer will be the act of joining two optical fibers end-to-end using heat. The goal is always to fuse both the fibers together such that light passing with the fibers is just not scattered or reflected back by the splice, therefore that the splice and the region surrounding it are almost as strong because the virgin fiber itself. The fundamental fusion splicer apparatus is made up of two fixtures on what the fibers are mounted and a couple electrodes.

Inspection microscope assists in the placement of the prepared fiber ends in a fusion-splicing apparatus. The fibers they fit to the apparatus, aligned, after which fused together. Initially, fusion splicing used nichrome wire as the heater to melt or fuse fibers together. New fusion-splicing techniques have replaced the nichrome wire with fractional co2 (CO2) lasers, electric arcs, or gas flames to heat the fiber ends, making them fuse together. The little size the fusion splice and the growth and development of automated fusion-splicing machines have made electric arc fusion (arc fusion) probably the most popular splicing techniques in commercial applications.

Splicing fiber optic cable ends together is often a precise process with almost no room for error. The reason being the optical fiber ends has to be gathered absolutely perfectly to be able to minimize potential optical loss or light leakage. Properly splicing the cable ends demands the use of a high-tech tool called a fusion splicer. A fusion splicer perfectly mates the optical fiber ends by melting or fusing them to one another. Splicing fiber cables is preferable to using connectors since fusing process results in a superior connection which has a dramatically reduced degree of optical loss. Now, I am going to introduces 4 steps to fusion splicing.

Step1

Know that fusion splicing is basically several optical fibers being permanently joined together by welding having an electronic digital arc. The need for an exact cleaver is suggested in case you desire less light loss and reflection problems. Understand that a quality cleaver just for this precise work is necessary. If the poor spice is created, the fiber ends may well not melt together properly and problems can arise.

Step2

Prepare the fiber by stripping the coatings, jackets and tubes, being sure that only bare fiber is left showing. You should clean each of the fibers of the filling gel. A clean environment is imperative for any good connection.

Step3

Cut the fiber. A great wire cutter is mandatory to acquire a successful splice. When fusing the fibers together, either aligns the fibers manually or automatic, determined by what sort of fusion splicer you might have. When you have bought a proper alignment, an electric arc can be used to melt the fibers together setting up a permanent weld of the two fiber ends.

Step4

Protect the fiber with heat shrink sleeve, silicone get. This will likely keep the optical fiber protected from any outside elements it might encounter or future breakage. Choices to fusion splicing include using fiber optic connectors or mechanical splices as both versions have higher insertion losses, lower reliability and higher return losses than fusion splicing. Want to know more about fiber splicer knowledge, please contact a Sopto representative by calling 86-755-36946668, or by sending an email to info@sopto.com.