-

- Sopto Home

-

- Special Topic

-

- Fiber Optics knowledge

-

- Anatomy of a Optical Fiber Cable

Fiber Optics knowledge

- Maintained Methods of Fusion Splicer Parts

- How to Use the Fiber Optic Cleaver?

- What are Fixed Attenuators & Variable Attenuators?

- Deployable Fiber Optic Systems for Harsh Mining Environments

- Developing Miniature Fiber Optic Cable Has Become the Trend

- Fiber Optic Cleaning Procedures

- 6 Steps to Selecting a Fiber Optic Cable

- Signal Attenuation Introduction

- How Fiber Transmission Works?

SOPTO Special Topic

Certificate

Guarantee

Except products belongs to Bargain Shop section, all products are warranted by SOPTO only to purchasers for resale or for use in business or original equipment manufacturer, against defects in workmanship or materials under normal use (consumables, normal tear and wear excluded) for one year after date of purchase from SOPTO, unless otherwise stated...

Return Policies

Defective products will be accepted for exchange, at our discretion, within 14 days from receipt. Buyer might be requested to return the defective products to SOPTO for verification or authorized service location, as SOPTO designated, shipping costs prepaid. .....

Applications

Fiber Optis can be used in so many fields:

Data Storage Equipment

Interconnects,Networking

Gigabit Ethernet

FTTx, HDTV,CATV

Aerospace & Avionics

Data Transfer Tests

Network Equipment

Broadcast Automotive

Electronics,Sensing

Oil & Gas, Imaging

Outside Plant,Central Office

Harsh Environment

Data Transmission

Illumination,Institutions

Ship to Shore,Education

Simulation,Military,Space

Unmanned Aerial Vehicles

Semiconductor Equipment

Diagnostics & Troubleshooting

Premise Networks Carrier Networks

Independent Telecommunication Providers

SOPTO Products

- Fiber Optic Transceiver Module

- High Speed Cable

- Fiber Optical Cable

- Fiber Optical Patch Cords

- Splitter CWDM DWDM

- PON Solution

- FTTH Box ODF Closure

- PCI-E Network Card

- Network Cables

- Fiber Optical Adapter

- Fiber Optical Attenuator

- Fiber Media Converter

- PDH Multiplexers

- Protocol Converter

- Digital Video Multiplexer

- Fiber Optical Tools

- Compatible

Performance Feature

Fiber Optics knowledge

Recommended

Anatomy of a Optical Fiber Cable

There’s a lot of emphasis in the government sector of the AV industry on using optical fiber due to its ability to prevent, or at least deter, security intrusions. Optical fiber also eliminates some other problems inherent in twisted-pair cable, such as near-end crosstalk (NEXT) and electromagnetic interference (EMI).

While fiber optic cable itself is cheaper than an equivalent length of copper cable, fiber optic cable connectors and the equipment needed to install them have typically been more expensive than their copper counterparts. With an increased emphasis on protecting digital information, however, optical fiber has become more cost-competitive over the last few years.

The ability of fiber optic cable to meet the evolving needs of government AV/IT end users is a good reason for integrators to know a little more about it. Here’s a look at the anatomy of a fiber optic cable.

Basic Construction of a Fiber Optic Cable

A fiber optic cable consists of five main components: core, cladding, coating, strengthening fibers, and cable jacket.

.png)

Basic Construction of a Fiber Optic Cable

Core: This is the physical medium that transports optical signals from an attached light source to a receiving device. The core is a single continuous strand of high-purity glass or plastic whose diameter is measured in microns (less than the diameter of a human hair). The larger the core, the more light the cable can carry, which correlates to a higher data transfer rate.

Cladding: This is a thin layer that is extruded over the core and serves as the boundary that contains the light waves (more on this later), enabling data to travel through the length of the fiber.

Coating: This is a plastic coating over the cladding to reinforce the fiber core, help absorb shocks, and provide extra protection against excessive cable bends. It does not have any effect on the optical waveguide properties, though.

Strengthening fibers: These components help protect the core against crushing forces and excessive tension during installation. The materials can range from Kevlar®, to wire strands, to gel-filled sleeves. Sometimes light-absorbing (“dark”) glass is added between the fibers, to prevent light that leaks out of one fiber from entering another. This reduces cross-talk between the fibers.

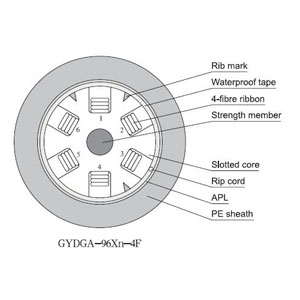

Slotted-Core Fiber Optic Cable with Aluminum

Cable jacket: This is the outer layer, or sheathing, of the cable. Its purpose is to protect the cable from environmental hazards, such as construction work, fishing gear, and even sharks, which are often attracted to the electrical fields created by signal conductors to repeaters.

Multi-Mode vs. Single-Mode Fiber

The main difference between multi-mode and single-mode optical fiber is that multi-mode has a larger core diameter, typically 50–100 micrometers; which is much larger than the wavelength of the light carried within it. The larger core allows multiple light rays or modes (modalities) to be transmitted concurrently, each at a slightly different angle of reflection within the optical fiber core. In practical terms, the larger core size simplifies connections and also allows the use of lower-cost electronics such as light-emitting diodes (LEDs) and vertical-cavity surface-emitting lasers (VCSELs).

.png)

Multi-Mode Fiber Transmission

However, multi-mode fiber transmission is used for relatively short distances because the modes tend to disperse/distort over longer lengths, resulting in an unclear and incomplete data transmission. For longer distances, single-mode fiber (sometimes called monomode) is used because it is not limited by modal dispersion.

Due to its high capacity and reliability, multi-mode optical fiber is mostly used for communication over short distances, such as within a building or on a campus. Typical transmission speed and distance limits are 100 Mbit/s for distances up to 2 km, 1 Gbit/s up to 1000 m, and 10 Gbit/s up to 500 m.

Bandwidth can be further increased by using wavelength-division multiplexing (WDM), a technology which multiplexes (“muxes”) a number of optical carrier signals onto a single optical fiber by using different wavelengths (i.e. colors) of laser light. This technique enables bidirectional communications over one strand of fiber, as well as increasing capacity.

A WDM system uses a multiplexer at the transmitter to join the signals together and a demultiplexer at the receiver to split them apart. With the right type of fiber it is possible to have a device that does both simultaneously. Modern WDM systems can handle up to 160 signals or more and can expand a 10 Gbit/s system over a single fiber pair to over 1.6 Tbit/s.

Sopto supplies a wide range of fiber optic cables, like Drainage Pipeline Cable, Direct Buried Fiber Optical Cable and cable tools and so on. For the newest quotes, please contact a Sopto representative by calling 86-755-36946668, or by sending an email to info@sopto.com. For more info, please browse our website.

-180x180.JPG)